Views: 58 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

Choosing the right cold room panels for sale helps you maintain strict temperature control and cut energy costs. Facilities using polyurethane panels can save up to 40% on energy compared to traditional insulation. High-quality panels reduce maintenance needs and lower operational costs, supporting facility longevity. Insulated metal panels often last 30 to 40 years and simplify installation, which means less downtime. You should consider technical specifications and practical needs to get the best results for your facility.

Choosing high-quality cold room panels can save you up to 40% on energy costs, improving your facility's efficiency.

Select panels with the right insulation material and R-value to maintain temperature and protect stored products.

Thicker panels provide better insulation; match the thickness to your facility's temperature needs for optimal performance.

Consider surface finishes that enhance hygiene and durability, especially for food storage environments.

Consult with experts to ensure you choose the right panels and installation methods for your specific requirements.

You need to select cold room panels for sale with the right insulation core material. The insulation core determines how well the panel keeps heat out and maintains low temperatures. The most common insulation materials include polyurethane (PU), polyisocyanurate (PIR), expanded polystyrene (EPS), and rock wool. Each material offers different thermal properties.

Insulation Material | R-value (per inch) | Characteristics |

|---|---|---|

PU/PIR | R-6.0 to R-8.0 | Excellent thermal insulation, minimizes heat intrusion, reduces energy consumption |

EPS | R-3.8 to R-4.4 | Lowest cost, suitable for low requirement applications, less efficient than PU/PIR |

Rock Wool | R-3.7 to R-4.2 | Similar to EPS, requires thicker boards for equivalent performance |

Panels with higher R-values provide better insulation. For commercial refrigeration, you should look for panels with R-values that match your temperature needs. The table below shows recommended R-values and panel thickness for different applications:

Application | Recommended Panel Thickness | Target Internal Temperature | Suggested R-Value |

|---|---|---|---|

Chiller Room | 80 – 100 mm | +2°C | 20 – 25 |

Freezer Room | 120 – 150 mm | -18°C | 30 – 40 |

Blast Freezer | 150 – 200 mm | -30°C | 40+ |

Choosing panels with the right insulation and R-value helps you save energy and keep products safe.

Panel thickness affects how well your cold room panels for sale perform. Thicker panels provide better insulation and help maintain stable temperatures. You should match the panel thickness to your facility’s temperature range.

For chiller rooms (0°C to 5°C), use panels between 75mm and 100mm thick.

For freezer rooms (-18°C and below), choose panels between 100mm and 150mm thick.

For ultra-low temperature storage (-40°C and below), select panels greater than 150mm thick.

Industry standards recommend minimum panel thickness based on temperature:

Temperature Range | Minimum Panel Thickness |

|---|---|

Medium Temperature (+10/-5°C) | 80mm |

Low Temperature (-15/-20°C) | 100mm |

Hot Regions (additional) | +20-50% thickness |

You should always check the recommended thickness for your application. Thicker panels help you reduce energy loss and improve efficiency.

The surface finish of cold room panels for sale impacts hygiene, durability, and safety. Food-grade finishes are essential for facilities storing perishable goods. You should choose panels with smooth or pebbled finishes for easy cleaning and impact resistance.

Surface Finish | Features |

|---|---|

Pebbled Texture Panel | Anti-aging, impact resistant |

Smooth Panel | Anti-aging, smooth glossy surface |

FRP Leaf Texture Panel | Anti-skid with gel coating |

Surface materials also affect hygiene and durability:

Surface Material | Characteristics | Hygiene and Durability Benefits |

|---|---|---|

Galvanized Steel | Lightweight, hygienic | Resistant to corrosion, suitable for food storage |

Stainless Steel | High resistance to wear | Superior durability and hygiene |

Fiberglass-Reinforced Plastic (FRP) | Lightweight, hygienic | Corrosion-resistant, easy to clean |

Polyester Coating | Enhances durability | Protects against environmental factors |

Antibacterial PVC | Hygiene-focused | Ideal for environments requiring high hygiene standards |

Tip: Choose antibacterial PVC or stainless steel finishes for environments that require strict hygiene standards.

Fire safety and moisture resistance are critical for cold room panels for sale. You should select panels that meet fire resistance standards such as ASTM E84-16 and EN 13501-01. These standards test flame spread and smoke production. PIR panels offer better fire resistance, often reaching B-s1,d0 under EN13501. PU panels usually have lower fire ratings.

PIR panels: Better fire resistance (up to B-s1,d0 under EN13501)

PU panels: Lower fire ratings

Compliance: FM Approval, EN 13501, ASTM E84

Moisture resistance prevents mold and bacteria growth. Panels with sealed surfaces and water-resistant finishes help you maintain a clean environment. You should always check for compliance with fire and hygiene standards before purchasing.

Selecting the right cold room panels for sale requires a careful evaluation of your facility’s needs, temperature requirements, and storage conditions. You can optimize energy efficiency, product safety, and long-term durability by matching panel specifications to your unique application.

Start by analyzing your facility’s specific requirements. Consider the following factors:

Identify the types of products you plan to store and their temperature sensitivity.

Determine the targeted temperature range for your cold storage.

Evaluate energy efficiency goals and fire safety requirements.

Review hygiene standards, especially if you store food or pharmaceuticals.

Perform technical calculations, such as heat gain/loss and condensation analysis.

Check for compliance with quality standards like TS EN 14509 and ISO 23953.

You should also review the physical aspects of your facility:

Measure available space and assess the layout for optimal workflow.

Ensure accessibility for loading and unloading.

Plan for proper ventilation and moisture control.

Analyze the installation location to confirm it meets local and international standards.

Tip: Always balance cost and performance. Consider insulation thickness, surface material, fire safety, and moisture resistance when comparing cold room panels for sale.

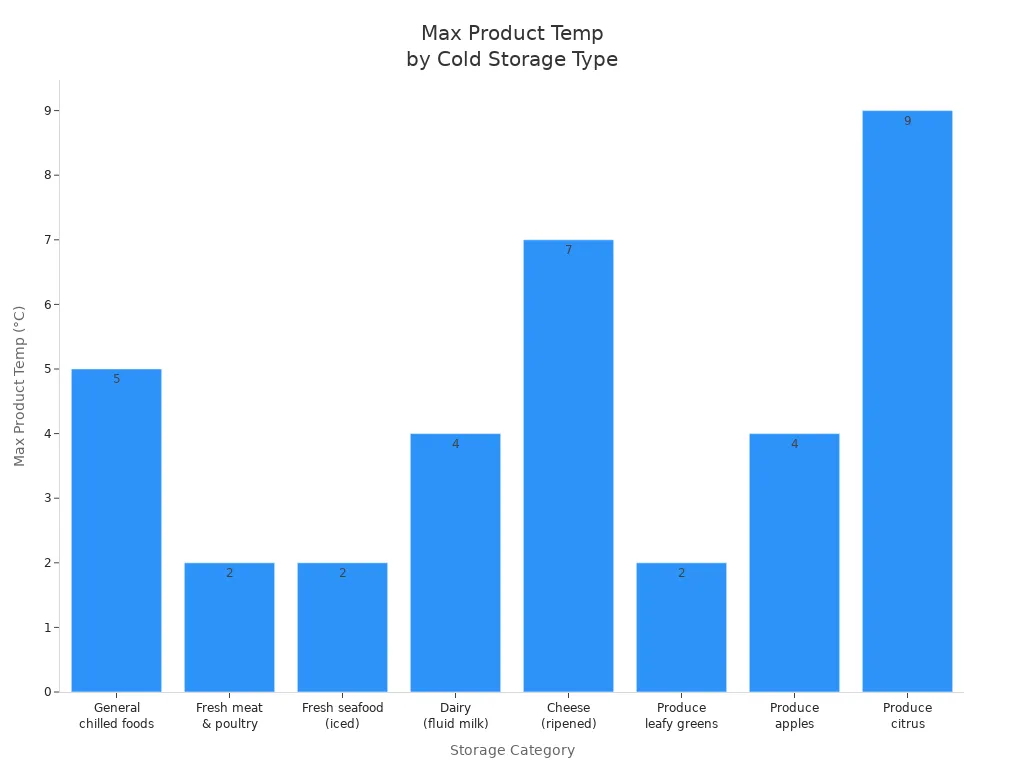

Temperature control is the core function of any cold storage facility. You must select panel specifications that align with your target temperature range. The thickness and insulation material of your panels play a crucial role in maintaining stable conditions and reducing energy consumption.

Category | Typical Setpoint | Control Band (Air) | Product Limit (Never Exceed) | Notes |

|---|---|---|---|---|

General chilled foods | 0–5 °C | ±1 °C | ≤5 °C | Many jurisdictions use 5 °C (41 °F) as a critical upper limit. |

Fresh meat & poultry | 0–2 °C | ±0.5–1 °C | ≤2 °C | Minimizes drip loss and microbial growth. |

Fresh seafood (iced) | –1 to 2 °C | ±0.5 °C | ≤2 °C | Slurry/flake ice contact preferred for core control. |

Dairy (fluid milk) | 1–4 °C | ±1 °C | ≤4 °C | Prevents souring; keep door cycles tight. |

Cheese (ripened) | 1–7 °C | ±1 °C | ≤7 °C | RH control is critical to avoid rind cracking. |

Produce – leafy greens | 0–2 °C | ±1 °C | ≤2 °C | High RH to prevent wilting; watch for freezing injury. |

Produce – apples | 0–4 °C | ±1 °C | ≤4 °C | Controlled-atmosphere helps; avoid ethylene with greens. |

Produce – citrus | 3–9 °C | ±1 °C | ≤9 °C | Some cultivars suffer chilling injury at very low temps. |

You should match the insulation thickness to your temperature needs:

Chiller rooms (0–5°C): 80–100 mm panels

Freezer rooms (–18°C): 100–150 mm panels

Blast freezers (–30°C): 150–200 mm panels

Selecting the right insulation type, such as polyurethane or rock wool, ensures optimal performance. Consult with mechanical engineers or local experts to determine the best paneling for your specific temperature requirements. Installing the correct panels during initial construction helps prevent cold air leaks and maintains efficiency.

The products you store directly influence your choice of cold room panels for sale. Each product category has unique storage needs that affect insulation, panel thickness, and surface finish.

Choose panels with the appropriate core type for your storage conditions.

Ensure thermal insulation covers walls, ceilings, and floors.

Optimize the combination of panel thickness and cooling equipment to reduce power consumption.

Use specialized cold room doors to minimize heat entry and maintain internal temperatures.

Implement thermal breaks to enhance insulation effectiveness.

For example, storing frozen foods or pharmaceuticals requires thicker panels and higher-grade insulation to maintain low temperatures. Fresh produce may need panels with moisture-resistant finishes to prevent spoilage. Always verify that your cold room panels for sale meet the necessary certifications and hygiene standards for your products.

Note: Lower temperature requirements demand thicker panels. For storage below –10°C, use panels at least 100 mm thick. For –20°C or lower, increase thickness to 140 mm or more.

By carefully assessing your facility, matching temperature requirements, and considering your product storage needs, you can select cold room panels for sale that deliver energy efficiency, product safety, and long-term value.

When you compare cold room panels for sale, you should start by looking at the materials and their features. Each material offers different levels of insulation, fire resistance, and suitability for specific applications. The table below helps you see how the main options stack up:

Material Type | Thermal Conductivity (W/m·K) | Insulation Performance | Fire Resistance | Applications |

|---|---|---|---|---|

Polyurethane (PU) | ~0.022 | Excellent | Moderate | Cold storage with insulation priority |

Polyisocyanurate (PIR) | ~0.020 | Excellent | Improved | Large facilities with fire safety needs |

Expanded Polystyrene (EPS) | ~0.036 | Lower | Lower | Smaller or budget cold rooms |

You should also consider advanced features that improve hygiene and efficiency:

Antimicrobial coatings help stop bacteria from growing, which keeps your cold room clean and safe.

Integrated vapor barriers block moisture, which protects insulation and prevents mold.

Tip: Choose panels with vapor barriers and antimicrobial surfaces for food or pharmaceutical storage.

Certifications and fire ratings show you how well cold room panels for sale meet safety and quality standards. Leading manufacturers test their panels for flame spread and smoke development. You should look for panels that meet standards like FM 4880, USDA, FDA, and UL fire ratings. The table below highlights how top manufacturers compare:

Manufacturer | Fire Rating Standards | Certifications |

|---|---|---|

KPS Global | Third-party fire rating processes | FM 4880 certification, insurance discounts |

ThermalCraft | PIR panels: 15 min to 3 hrs; Mineral wool: up to 3 hrs | USDA, FDA, FM Class 1 fire performance |

Metlspan | Non-combustible mineral wool core | UL fire rated panel systems |

Panels with mineral wool cores can resist fire for up to three hours. PIR panels offer fire integrity from 15 minutes to three hours. You should always check for certifications before you buy.

Choosing the right supplier helps you get reliable cold room panels for sale and strong after-sales support. You should:

Research supplier reputations and read customer reviews.

Look for warranties that last one to five years and ask about extended options.

Check for technical support, online guides, and spare parts availability.

Positive reviews show that a supplier delivers durable and efficient panels. Reliable suppliers offer troubleshooting help and quick access to replacement parts.

Note: A good supplier stands behind their products and supports you after installation.

You want to get the best value for your investment. Balancing cost and quality is key when choosing cold room panels. Several factors affect the total price and long-term savings. The table below highlights what you should consider:

Factor | Description | Impact on Cost |

|---|---|---|

Size and Capacity | Larger rooms need more materials and complex installation. | Higher costs for bigger spaces. |

Insulation and Materials | High-quality insulation improves energy efficiency and saves money over time. | Premium materials cost more but lower future bills. |

Temperature Range | Extreme temperatures require specialized components. | Higher upfront costs for special systems. |

Customization | Tailored features add to the price. | Customization can increase costs by 15%-30%. |

Refrigeration System | Efficient systems use less energy. | Advanced systems cost more but save energy. |

Tip: Investing in better insulation and efficient systems can reduce your energy bills and maintenance costs over the years.

Expert advice helps you avoid common mistakes and ensures your cold room performs well. Here are some ways experts can help:

They guide you in choosing the right core material for your needs.

They help you select the correct panel thickness for your climate and storage goals.

They consider building orientation and sunlight exposure to boost insulation.

They recommend high-quality seals and joints to prevent air leaks.

They remind you not to focus only on the lowest price, but to weigh long-term benefits.

Note: Always ask for technical support and clear documentation from your supplier. This includes installation instructions, maintenance guidelines, and quality certificates.

After you select your supplier, follow these steps for a smooth installation:

Choose a location away from heat sources.

Plan the layout for efficient storage and movement.

Clean and prepare the room before installation.

Install insulation and secure moisture-resistant flooring.

Hire a qualified technician for the refrigeration system.

Set up ventilation and lighting that meet safety standards.

Schedule regular maintenance checks.

Request the following documents and support from your supplier:

Documentation Type | Description |

|---|---|

Technical specifications | Details about the panels and their performance. |

Quality certificate | Proof of panel quality and safety. |

Installation instructions | Step-by-step guidance for proper setup. |

Maintenance guidelines | Tips for keeping your panels in top condition. |

Support services | Access to technical help and training. |

��️ Careful planning and expert support help you get the most from your investment and ensure your cold room runs efficiently.

Choosing high-quality cold room panels for sale gives you long-term benefits. You can expect:

Up to 30% energy savings from excellent thermal insulation

Lower operational costs and energy bills

Improved hygiene and product safety that meets food standards

Protection from contamination for stored items

Consulting with cold room panel suppliers helps you find panels that fit your needs. Expert advice ensures you get the right material, thickness, and size for your facility. Review your options and request quotes from trusted cold room panel manufacturers to maximize value and performance.

You should check the insulation type, panel thickness, and fire resistance. Ask cold room panel suppliers about certifications. Reliable cold room panel manufacturers provide technical support and clear documentation. Always compare options before you buy.

Start by searching for cold room panels near me. Read customer reviews and check for industry certifications. Trusted cold room panel manufacturers offer warranties and after-sales support. You can also request references from other buyers.

Yes. Cold room panels for sale work in food storage, pharmaceuticals, and floral industries. Cold room panel suppliers can recommend the best panels for your needs. Always match the panel type to your storage requirements.

Clean the panels regularly with mild detergent. Inspect for damage or moisture. Cold room panel manufacturers suggest checking seals and joints. Schedule routine maintenance with your cold room panels supplier to keep your system efficient.

You should receive technical specifications, installation instructions, and quality certificates. Leading cold room panel manufacturers also offer maintenance guidelines and support services. Always keep these documents for future reference.