Views: 203 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

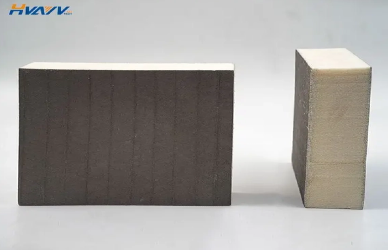

Proper insulation plays a crucial role in commercial buildings by significantly improving energy efficiency, reducing operational costs, and enhancing overall occupant comfort. Effective insulation helps maintain consistent indoor temperatures year-round, minimizing the workload on heating, ventilation, and air conditioning (HVAC) systems. PU foam boards are an excellent choice for commercial insulation due to their superior thermal resistance, outstanding moisture resistance, and long-lasting durability. These characteristics make PU foam boards especially beneficial for commercial applications where sustained energy savings and reliable long-term performance are essential to building owners and occupants alike.

Before installing PU foam boards, it is important to evaluate the building’s specific insulation needs. This includes considering local climate, architectural design, and energy efficiency goals. A careful assessment ensures the chosen insulation meets thermal performance standards and helps identify challenges, allowing for a tailored strategy to reduce energy use and improve occupant comfort.

Choosing the right type and thickness of PU foam board is key to achieving effective insulation. Factors include the required R-value, available installation space, and application areas such as walls, roofs, or floors. Higher R-value boards can allow for thinner layers, beneficial in tight spaces. Selecting appropriate thickness balances cost and performance for maximum energy savings and durability.

It is crucial to ensure PU foam boards are compatible with other building materials like vapor barriers, structural elements, and finishes. Proper compatibility prevents moisture buildup, chemical reactions, or degradation that could reduce insulation effectiveness. Coordinating materials early ensures a durable, efficient insulation system that supports long-term building performance.

Before installing PU foam boards, it is crucial to thoroughly clean and prepare all surfaces that will receive the insulation. This includes removing any dust, dirt, grease, oils, and loose or flaky materials that may interfere with proper adhesion and fitting of the boards. Ensuring that the surfaces are smooth, dry, and stable not only aids in better attachment but also maximizes the long-term effectiveness and durability of the insulation. Proper surface preparation reduces the risk of future problems such as detachment or gaps that could compromise the insulation’s thermal performance.

Effective moisture management plays a vital role in protecting both the building structure and the PU foam boards from damage. Installing suitable vapor barriers and moisture control layers before placing the insulation helps prevent condensation buildup, mold growth, and potential rot. This is particularly important in areas subject to high humidity, frequent water exposure, or varying seasonal moisture levels. Correctly addressing moisture control during site preparation ensures a healthier indoor environment and extends the lifespan of the insulation system.

Creating and maintaining a safe working environment during the installation of PU foam boards is essential to protect workers’ health and safety. All personnel involved should wear appropriate personal protective equipment (PPE), including gloves, dust masks or respirators, and safety goggles, to reduce exposure to dust, chemical irritants, or potential allergens. Clear communication among the installation team, combined with strict adherence to safety protocols and training, helps minimize workplace accidents and promotes efficient and smooth project completion. Ensuring safety not only protects workers but also supports higher quality workmanship.

When working with PU foam boards, use appropriate cutting tools such as utility knives or saws to achieve clean and precise cuts. Always wear protective gloves and eyewear to prevent injuries. Handle boards carefully to avoid damage, as cracks or breaks can compromise insulation performance.

Ensure that PU foam boards fit snugly against surfaces without gaps or overlaps. For walls and roofs, install boards in a staggered pattern to reduce thermal bridging. On floors, lay boards on a stable, level base to maintain structural integrity and consistent insulation coverage.

Properly sealing all joints, seams, and gaps between PU foam boards is critical to effectively prevent air leakage and minimize heat loss. To achieve this, it is important to use compatible sealing materials such as specialized tapes, high-quality sealants, or expanding spray foam. Creating a continuous and airtight barrier not only enhances the overall thermal performance of the insulation system but also contributes to improved energy efficiency and indoor comfort throughout the building.

Depending on the application, combine adhesives with mechanical fasteners such as screws or pins to secure PU foam boards firmly in place. Adhesives provide uniform bonding, while fasteners add mechanical strength, especially in vertical or overhead installations.

PU foam boards, while moisture-resistant, still require protection from direct water exposure and prolonged UV radiation. Installing appropriate vapor barriers and waterproof membranes prevents moisture infiltration that could compromise insulation performance. Additionally, shielding PU foam boards from sunlight using protective coatings or facings helps prevent material degradation caused by UV rays.

Adequate ventilation is crucial both during the installation process and in the completed building to avoid trapped moisture and ensure healthy indoor air quality. Proper airflow helps dry out any residual moisture and reduces the risk of mold growth. Incorporating ventilation strategies, such as air gaps or mechanical ventilation systems, supports the longevity and effectiveness of PU foam board insulation.

After installing PU foam boards, it is important to carefully inspect all surfaces for any gaps, compression marks, or physical damage. Even small gaps can significantly reduce insulation effectiveness by allowing unwanted air infiltration. Compressed or damaged boards may lose their thermal insulating properties, which can compromise the overall performance of the building envelope. Any such issues should be promptly addressed to maintain optimal insulation efficiency and prevent further deterioration.

Conducting tests or using infrared cameras to verify the installed PU foam insulation’s thermal resistance and airtightness is highly recommended. Ensuring a tight and well-sealed building envelope helps minimize energy loss, leading to improved indoor comfort and lower heating or cooling costs. These assessments can also identify problem areas that require additional sealing or repair, helping maintain the long-term effectiveness of the insulation system.

Regular maintenance plays a key role in prolonging the lifespan and performance of PU foam board insulation. It is important to keep insulation areas dry and protected from physical or mechanical damage. Scheduling periodic inspections allows early detection of signs of wear, moisture intrusion, or any other issues, enabling timely intervention before problems escalate. Proper maintenance ensures that the insulation continues to provide efficient thermal protection for many years.

Proper installation of PU foam boards is essential to fully realize their benefits in commercial building insulation. Key tips include careful surface preparation, precise cutting and fitting, thorough sealing of joints, and protecting the boards from moisture and UV damage. Following these best practices ensures long-term insulation performance, energy efficiency, and durability.

For professional advice and high-quality PU foam board solutions, consider reaching out to Huayu New Tech (Beijing) International Trade Co., Ltd. Their expertise can help you optimize insulation in your commercial projects and achieve lasting results.