Views: 36 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

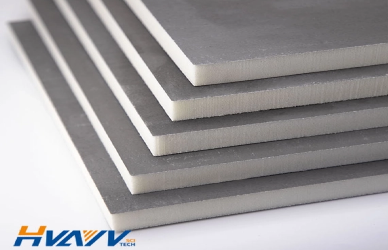

Airtightness is a critical factor in building insulation, directly impacting energy efficiency, indoor comfort, and moisture control. Minimizing air leakage helps reduce unwanted heat loss or gain, lowering energy consumption and utility costs. Polyiso board, known for its excellent thermal insulation properties and rigid structure, plays a key role in creating an effective building envelope. This article aims to explore practical and effective methods to prevent air leakage when installing polyiso board, ensuring optimal insulation performance and long-term building efficiency.

Air leakage refers to the unintended flow of air through cracks, gaps, and openings in a building’s envelope. This uncontrolled airflow bypasses insulation materials like polyiso boards, reducing their effectiveness.

Gaps and seams between insulation boards

Openings around windows, doors, and utility penetrations

Junctions where insulation meets structural components such as walls and roofs

Energy Loss: Air leakage causes heat to escape during cold weather and enter during warm weather, increasing heating and cooling costs.

Moisture Problems: Warm, moist air infiltrating cold areas can lead to condensation, promoting mold growth and material deterioration.

Reduced Comfort and Indoor Air Quality: Drafts and moisture issues can lead to discomfort and poor indoor environmental conditions.

Controlling air leakage is crucial for maximizing the thermal performance of polyiso boards and ensuring the longevity and health of the building.

Before installing polyiso boards, it is essential to prepare the surface properly. The surface should be clean and free from any moisture to promote strong adhesion and effective sealing. A smooth surface ensures that the insulation boards fit tightly without gaps or unevenness that could compromise airtightness.

Any dirt, dust, or loose debris on the installation surface can weaken the bonding between the polyiso boards and the substrate. Thorough cleaning using brushes, vacuums, or air blowers is recommended to remove these particles, helping to create a reliable seal and improve overall insulation performance.

Prior to placing the polyiso boards, inspect the installation area for any existing gaps, cracks, or damaged areas. These should be repaired with appropriate fillers or sealants to prevent air infiltration points. Addressing these imperfections ensures a continuous, airtight insulation layer once the polyiso boards are installed.

To maximize insulation efficiency and airtightness, it is crucial to install polyiso boards with tight, gap-free joints. Carefully align each board edge-to-edge, avoiding spaces that could allow air leakage. Using precision cutting tools helps achieve clean edges, enabling boards to fit snugly together and form a continuous thermal barrier.

Implementing a staggered joint pattern—where seams between boards do not line up—reduces thermal bridging and strengthens the overall insulation layer. This technique breaks up linear gaps that could conduct heat and allows for better structural stability, improving both energy efficiency and durability.

Selecting polyiso boards with appropriate thickness and dimensions ensures a proper fit within the building assembly. Boards that are too thin may compromise thermal resistance, while oversized boards can be difficult to install correctly. Matching board size to the cavity or surface dimensions helps create a compact, well-sealed installation, enhancing the overall insulation performance.

To ensure effective airtightness, it is important to use sealants and tapes specifically designed to work with polyiso boards. Commonly recommended products include acrylic-based sealants, butyl tapes, and specialized insulation tapes that adhere well to the smooth surfaces of polyiso. These materials provide strong bonding, flexibility, and durability, resisting environmental stresses such as temperature changes and moisture exposure.

Clean the Surface: Before applying any sealant or tape, ensure that the edges and joints of the polyiso boards are free from dust, dirt, and moisture to promote adhesion.

Apply Sealant: Use a caulking gun to apply a continuous bead of sealant along the joints and board edges, filling any gaps or cracks.

Smooth the Sealant: Use a putty knife or gloved finger to smooth out the sealant, ensuring it fully contacts both board surfaces and fills the joint evenly.

Apply Tape: Immediately after sealing, press the compatible tape firmly over the sealed joints to reinforce the airtight barrier.

Inspect for Gaps: Check the sealed area for any missed spots or thin coverage, and reapply sealant or tape as necessary to maintain continuity.

Maintaining a continuous, uninterrupted seal along all joints and seams is vital for preventing air leakage. Even small gaps can compromise the insulation’s thermal performance by allowing drafts and moisture infiltration. Proper sealing enhances energy efficiency, reduces heating and cooling costs, and protects the building structure from potential moisture damage and mold growth. Consistent sealing also helps extend the lifespan of the insulation system, ensuring long-term airtightness and durability.

For a strong installation of polyiso boards, use both adhesives and mechanical fasteners. Adhesives create uniform bonding across the board, reducing air gaps. Fasteners like screws or anchors provide extra holding strength, especially on walls or ceilings. Together, they ensure the insulation stays firmly in place under various conditions.

Over-fastening can compress or damage polyiso boards, causing cracks or gaps around fasteners. This weakens insulation and allows air leaks. Follow manufacturer recommendations on fastener number and spacing to avoid damaging the boards and maintain airtightness.

Place fasteners away from board edges and joints to protect sealed seams. Typically, fasteners go in the center areas of boards in a regular pattern for even hold without breaking seals. Proper fastener placement combined with sealed joints helps maintain an airtight barrier and improve energy efficiency.

After installing polyiso boards, carefully inspect all joints, seams, and edges for visible gaps or incomplete sealing. Properly sealing these areas is essential to ensure airtightness and optimal insulation performance.

Use blower door tests to measure air leakage by pressurizing the building, and infrared thermography to spot cold areas caused by hidden leaks. These tools help detect air infiltration that may not be visible during visual inspection.

Once leaks are found, seal them quickly with appropriate materials like sealants or tapes. Timely repairs help maintain energy efficiency, prevent moisture issues, and improve indoor comfort.

Routine checks of polyiso board insulation and all sealing materials are essential to maintain airtightness. Look for signs of wear, gaps, or deterioration in joints, seams, and fasteners to catch potential issues early before they affect performance.

Any damage from physical impacts, such as accidental knocks during maintenance or construction work, or weather-related wear like water infiltration or UV exposure, should be repaired promptly. Fixing cracks, holes, or compromised seals helps prevent air leaks and preserves the insulation’s effectiveness.

Engaging qualified professionals for periodic maintenance ensures that inspections and repairs are thorough and effective. Expert evaluation can identify hidden problems and recommend appropriate solutions, helping to extend the lifespan of polyiso board insulation and maintain building energy efficiency over time.

Preventing air leakage during the installation of polyiso boards is vital for maximizing energy efficiency and ensuring long-term building performance. Key methods include preparing clean and smooth surfaces, fitting boards tightly with staggered joints, properly sealing all seams and joints, and using mechanical fasteners and adhesives correctly. Regular inspection and maintenance further preserve airtightness over time.

To achieve the best results, it is essential to follow these best installation practices carefully. For reliable, high-quality polyiso boards and professional guidance, consider consulting industry experts like Huayu New Tech (Beijing) International Trade Co., Ltd. They offer superior materials and technical support to help you optimize insulation performance and building efficiency.