Views: 258 Author: Site Editor Publish Time: 2025-08-01 Origin: Site

PU foam boards, or polyurethane foam boards, are widely used insulation materials in construction. They have a rigid foam core that offers excellent thermal insulation, thanks to low thermal conductivity and high durability. Lightweight and easy to install, PU foam boards help improve building energy efficiency.

With rising energy costs and environmental concerns, energy-efficient buildings are increasingly important. Proper insulation reduces heat loss and gain, lowering heating and cooling energy use, saving costs, and reducing carbon emissions.

This article explores how PU foam boards enhance building insulation efficiency by examining their properties, uses, and energy-saving benefits, helping builders and homeowners choose effective insulation solutions.

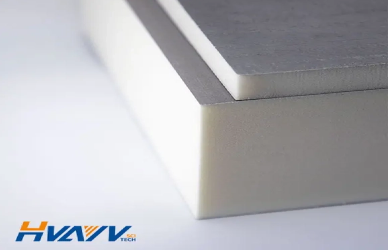

A PU foam board, or polyurethane foam board, is a rigid insulation panel made primarily from polyurethane, a polymer composed of organic units joined by carbamate (urethane) links. These boards consist of a closed-cell foam core, which provides excellent thermal insulation and structural strength. The core is typically sandwiched between protective facings such as aluminum foil or coated paper to enhance durability and moisture resistance.

PU foam boards are produced through a chemical reaction between polyols and isocyanates, which creates a foam that expands and hardens into a solid panel. This process involves precise control of temperature, pressure, and chemical ratios to achieve consistent density and insulation performance. After forming, the boards are cut to size and laminated with facing materials for added protection.

PU foam boards are known for their low thermal conductivity, typically ranging from 0.020 to 0.028 W/m·K, which makes them highly effective insulators. They are lightweight yet rigid, with good compressive strength and dimensional stability. Chemically, polyurethane foam is resistant to moisture, chemicals, and aging, ensuring long-lasting performance in various environmental conditions.

PU foam boards are highly valued for their exceptionally low thermal conductivity, typically ranging between 0.020 and 0.028 W/m·K. This means they effectively reduce heat transfer through walls, roofs, and floors, maintaining comfortable indoor temperatures. The low thermal conductivity helps minimize energy loss, which directly contributes to lower heating and cooling costs in buildings.

The insulation efficiency of PU foam boards depends largely on their thickness. Thicker boards provide greater thermal resistance (R-value), enhancing their ability to slow heat flow. This means that even relatively thin PU foam boards can achieve excellent insulation performance, making them suitable for space-limited applications without compromising energy savings.

Compared to common insulation materials such as EPS (expanded polystyrene) foam boards and fiberglass, PU foam boards offer superior insulation performance. EPS typically has a higher thermal conductivity (around 0.035 W/m·K), making PU foam boards more effective at the same thickness. Fiberglass insulation, while effective in certain applications, often requires greater thickness to match the thermal resistance of PU foam boards and is less resistant to moisture, which can degrade its performance over time.

Thermal resistance, commonly known as the R-value, measures a material’s ability to resist heat flow. The higher the R-value, the better the insulation performance. PU foam boards typically have a high R-value, often ranging between 6 to 7 per inch of thickness, which is significantly higher than many traditional insulation materials. This superior thermal resistance means that PU foam boards can effectively reduce heat transfer, keeping indoor spaces warmer in winter and cooler in summer, ultimately lowering energy consumption for heating and cooling.

PU foam boards not only provide excellent thermal insulation but also act as an effective barrier against air infiltration. By minimizing drafts and uncontrolled airflow, these boards help reduce unwanted heat loss or gain. Additionally, their closed-cell structure offers outstanding moisture resistance, preventing water vapor from penetrating the building envelope. This feature is crucial in avoiding condensation, mold growth, and structural damage, thereby preserving both indoor air quality and the integrity of the building.

Beyond insulation, PU foam boards contribute to the structural stability of buildings. Their rigid nature and high compressive strength provide added support to walls and roofs, enhancing overall durability. This structural strength ensures that the insulation performance remains consistent over time, as the boards resist deformation and maintain their shape under load, even in challenging environmental conditions.

PU foam boards are lightweight compared to many other insulation materials, which reduces the overall load on building frameworks. This makes them especially advantageous for retrofit projects or structures with weight limitations. Furthermore, their ease of handling and simple installation process save significant labor time and costs. The boards can be quickly cut and fitted into place, allowing for efficient construction and renovation workflows.

PU foam boards are versatile insulation materials suitable for various parts of a building. In walls, they are commonly used as continuous insulation layers that reduce thermal bridging and improve overall energy efficiency. On roofs, PU foam boards provide superior insulation against heat gain in summer and heat loss in winter, helping to maintain stable indoor temperatures. Foundations and basements also benefit from PU foam board insulation, as their moisture resistance prevents water infiltration while improving thermal protection below grade, which reduces heating costs and protects structural elements from freeze-thaw damage.

In residential buildings, PU foam boards are widely used in exterior walls and attic spaces to meet stringent energy codes and improve occupant comfort. Their lightweight and thin profile make them ideal for retrofitting older homes without compromising living space. In commercial construction, PU foam boards are employed in insulated panels for cold storage warehouses, refrigerated transport facilities, and office buildings, where maintaining controlled temperatures is critical. Many large-scale projects utilize PU foam board insulation for its durability and energy-saving benefits, contributing to sustainable building certifications such as LEED.

PU foam boards play a vital role in reducing energy consumption in buildings by providing superior thermal insulation. By minimizing heat transfer through walls, roofs, and floors, they significantly lower the demand for heating and cooling systems. This reduction in energy use translates directly into lower utility bills for building owners and occupants. Moreover, decreased reliance on fossil fuel-based energy sources helps reduce greenhouse gas emissions, contributing positively to global efforts against climate change.

PU foam boards align well with various international green building standards and certification programs such as LEED (Leadership in Energy and Environmental Design), BREEAM (Building Research Establishment Environmental Assessment Method), and WELL Building Standard. Their high insulating efficiency, durability, and contribution to improved indoor environmental quality help projects achieve key sustainability benchmarks. Additionally, many manufacturers produce eco-friendly PU foam boards using blowing agents with low global warming potential (GWP), further enhancing their environmental credentials.

PU foam boards offer numerous advantages that make them an excellent choice for improving building insulation efficiency. Their superior thermal resistance, effective air and moisture barriers, strong structural support, and ease of installation combine to deliver outstanding energy savings and long-lasting performance. These benefits not only reduce heating and cooling costs but also contribute to environmental sustainability by lowering carbon emissions.

For builders, architects, and homeowners seeking reliable and efficient insulation solutions, adopting PU foam boards is a smart decision. To learn more about high-quality PU foam boards and tailored insulation options, consider reaching out to Huayu New Tech (Beijing) International Trade Co., Ltd. Their expertise and innovative products can help you achieve superior building performance and energy efficiency.