Views: 77 Author: Site Editor Publish Time: 2025-10-13 Origin: Site

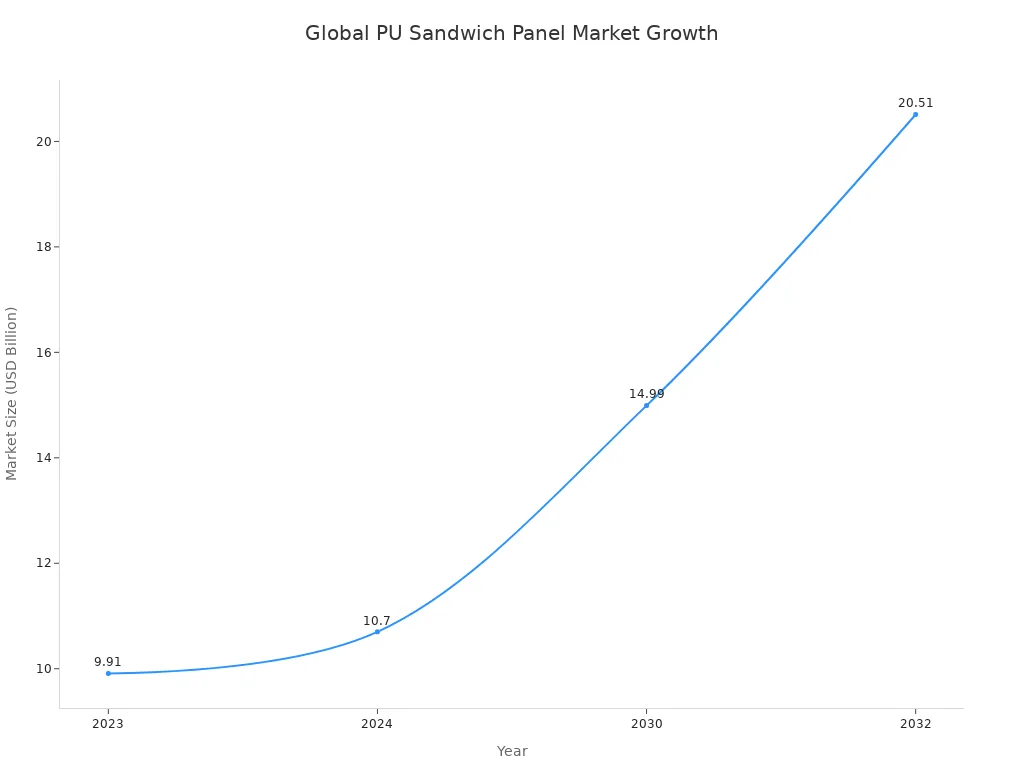

When choosing a PU sandwich panel manufacturer for your project, it’s important to make an informed decision. The global PU sandwich panel market reached $10.70 billion in 2024 and is expected to continue growing steadily, as illustrated below.

A reputable PU sandwich panel manufacturer can supply products for a wide range of applications. These panels are commonly used for roofing, wall cladding, and modular buildings. The table below outlines these key uses.

Application Type | Description |

|---|---|

Roofing | Provides thermal insulation and helps lower energy costs. |

Wall Cladding | Weather-resistant and ideal for challenging environments. |

Modular Buildings | Enables rapid construction and flexible design options. |

Focus on product quality and durability. Choose manufacturers that use advanced technology for consistent performance and long-lasting panels.

Check for certifications. Look for ISO 9001 and CE Certification to ensure safety and compliance with industry standards.

Consider customization options. Select manufacturers that offer flexibility in panel design, dimensions, and colors to meet your specific project needs.

Evaluate energy efficiency. Opt for PU sandwich panels with high R-values to reduce energy costs and improve insulation.

Prioritize after-sales support. Choose manufacturers that provide technical assistance and project guidance to ensure successful installation and performance.

When you select a PU sandwich panel manufacturer, you need to focus on several essential factors. These criteria help you find high quality products that deliver durability and reliability for your project.

You want panels that last and perform well in different environments. PU sandwich panels stand out for their lightweight design, which makes installation easier and reduces emissions from heavy machinery. Their durability depends on the right finishes and the conditions where you install them. Leading sandwich panel manufacturers use advanced technology and automated production lines to ensure consistent quality. Key features like thermal insulation, structural integrity, corrosion resistance, and vapor barriers all contribute to long-term reliability.

Factor | Description |

|---|---|

Thermal Insulation | Maintains stable temperatures and protects products and workers. |

Structural Integrity | Strengthens buildings and reduces risks in harsh conditions. |

Corrosion Resistance | Prevents damage in tough environments, improving safety. |

Vapour Barrier | Stops condensation and ice, ideal for cold storage. |

Certifications show that a manufacturer meets strict safety and performance standards. Look for ISO 9001 for quality management, CE Certification for fire and mechanical safety, and Bs1d0 or EN 13501-1 for fire resistance. These certifications ensure that the PU sandwich panel you choose will meet regulations and keep your building safe.

Tip: Always ask for material performance test reports, which cover compressive strength, thermal conductivity, and sound insulation.

Every project is unique. Top manufacturers offer flexibility in color, dimensions, thickness, and shape. You can choose from a wide range of colors, such as Alabaster, Sapphire Blue, or Brick Red, to match your design. Customization ensures the panels fit your needs, whether you want better insulation, a specific look, or creative layouts.

PU sandwich panels provide excellent energy efficiency. They have a higher R-value per inch than traditional materials, so you get better insulation in a thinner panel. This means lower energy bills and less maintenance over time. For example, some panels offer thermal conductivity as low as 0.19 W/mK, helping you maintain comfortable indoor temperatures and reduce costs.

Reliable after-sales support makes a big difference. Leading manufacturers offer services like project design, installation help, and technical assistance. Good support increases customer satisfaction and ensures your products perform well for years. Companies that focus on customer care build strong relationships and stay competitive.

Choosing the right pu sandwich panel manufacturer can make a big difference in your project’s success. You need to know how each company stands out, what products they offer, and how their pu sandwich panel machine technology affects quality and price. Here are profiles of the top sandwich panel manufacturers you should consider.

Kingspan Group leads the industry with advanced pu sandwich panel solutions. You get panels with high insulation efficiency, which helps you save energy and lower costs. Kingspan focuses on sustainability, so their products support green building goals. Their pu sandwich panel machine uses advanced technology to ensure consistent quality and strict standards. Kingspan stands out as an industry leader in cold room panels, making them a top choice for temperature-sensitive projects.

You benefit from comprehensive customer service, including detailed installation manuals and expert guidance.

Kingspan prioritizes customer satisfaction, so you receive support throughout your project.

Their panels help you achieve energy savings and meet strict certification requirements.

If you want reliable products and strong after-sales support, Kingspan offers a great balance of quality and price. Their reputation as a pu sandwich panel manufacturer means you can trust their solutions for demanding applications.

ArcelorMittal is recognized worldwide as a leader in steel and sandwich panel manufacturing. You get pu sandwich panels known for high performance, durability, and energy efficiency. The company invests in sustainable and innovative solutions, so you can choose environmentally friendly products for your building.

ArcelorMittal’s strong brand reputation gives you confidence in their products.

Their extensive distribution network makes it easy to source panels across Europe and beyond.

You benefit from panels designed for long-term reliability and reduced maintenance costs.

When you compare pu sandwich panel price and machine factory capabilities, ArcelorMittal’s scale and expertise help keep costs competitive. Their focus on quality and sustainability makes them one of the top sandwich panel manufacturers in the market.

Tata Steel offers pu sandwich panels with a contemporary design style and metal panel material. You can use their products for hotel applications and other commercial buildings. Tata Steel provides total project solutions, including cross-category consolidation, so you get everything you need from one source.

Key Attributes | Description |

|---|---|

Design Style | Contemporary design for modern buildings |

Application | Hotel and commercial projects |

Material | Metal panel for strength and durability |

Project Solution Capability | Complete solutions, including installation and training |

Warranty | 1-year warranty for peace of mind |

Technical Support | Online and onsite support, training, and inspection |

After-sale Service | Free spare parts, return, and replacement |

Tata Steel holds a significant market share, especially when combined with Metecno. You benefit from strong technical support and after-sales service, which helps you manage pu sandwich panel machine installation and maintenance. Their products offer good value for pu sandwich panel price, making them a reliable choice among sandwich panel manufacturers.

Company | Market Share (%) |

|---|---|

Kingspan | 20 |

Tata Steel | 15 (with Metecno) |

Metecno | 15 (with Tata Steel) |

Others | N/A |

Rautaruukki Corporation uses innovative technology in their pu sandwich panel machine production. You get panels with thickness options from 100 to 150 mm, factory-fitted seals for airtightness, and excellent energy efficiency. Their panels can decrease energy costs and CO2 emissions by up to 30%. You also earn more credits in LEED and BREEAM certification systems when you use their products.

Feature | Description |

|---|---|

Thickness | 100 - 150 mm |

Airtightness | Factory-fitted seals reduce energy loss |

Energy Efficiency | Up to 30% lower energy costs and emissions |

Certification Credits | More LEED and BREEAM credits |

Load-Bearing Capacity | Up to 40% higher than standard panels |

Fire Resistance | Very good fire resistance for safety |

Core Material | Rigid, HCFC-free, self-extinguishing PIR foam |

Thermal Insulation | Excellent insulation, reduced panel thickness lowers costs |

You can use Rautaruukki’s pu sandwich panels in washing chambers, swimming pools, factories with high humidity, and buildings near water. Their pu sandwich panel machine factory ensures consistent quality and compliance with international standards. If you need panels for challenging environments, Rautaruukki offers reliable products with strong performance.

Application Area | Description |

|---|---|

Washing chambers | Low hygroscopic foam core for moisture resistance |

Swimming pools | Effective in high humidity |

Factories with high humidity | Designed to withstand moisture |

Objects located near water | Moisture-resistant panels for coastal locations |

Qatar Steel Company has built a strong reputation in the Middle East as a pu sandwich panel manufacturer. You get panels with flame retardant properties that help delay fire hazards and provide moisture protection. Their products keep buildings cool in summer and warm in winter, improving thermal efficiency.

The dense core materials offer effective sound insulation, absorbing and blocking noise for quieter indoor spaces.

These features make Qatar Steel panels ideal for urban buildings and noisy environments.

Their state-of-the-art pu sandwich panel machine factory ensures high quality and industry-specific standards.

Aspect | Details |

|---|---|

Market Position | Strong reputation in the Middle East |

Focus Areas | Quality, customer satisfaction, sustainability, innovation |

Manufacturing Facility | Advanced factory for consistent quality |

Product Range | PU foam insulated sandwich panels and steel products |

Customer Base | Known for quality products and reliable service |

Qatar Steel’s focus on fire resistance, soundproofing, and moisture protection makes their panels a smart choice for safety and comfort. You can trust their products for demanding projects, and their competitive pu sandwich panel price adds value.

Shanghai Sunnyda House specializes in modular building solutions using pu sandwich panels. You can choose from thickness options of 50, 75, 100, or 150 mm, with steel plate thickness starting at 0.4 mm. Sunnyda offers a wide range of colors, including white, gray, silver, blue, red, and orange, so you can customize your building’s appearance.

Feature | Details |

|---|---|

Brand name | Sunnyda |

Thickness options | 50/75/100/150mm |

Steel plate thickness | 0.4mm or more |

Color options | white, gray, silver, blue, red, orange, etc. |

Customization | Personalized design and customization services |

Shipment methods | By air, sea, land, or express |

Effective width | 920/1000/1120mm |

Maximum panel length | Up to 11.8m |

Joint styles | Hidden joint, male and female joint |

Steel plate colors | Various colors as per RAL color |

Recommended coatings | SMP, HDP, PVDF, Polyester, PE, etc. |

Sunnyda’s pu sandwich panel machine factory uses CNC cutting machines and precision equipment to ensure high quality. The company employs experienced personnel, including architects and engineers, to oversee production. Sunnyda has passed ISO9001 and ISO14001 certifications, so you know their products meet international standards.

Sunnyda’s repeat order rate exceeds 90%. You benefit from long-term cooperation and strong client support, no matter the size of your order.

If you need modular buildings with flexible design and reliable performance, Sunnyda offers pu sandwich panels that combine customization, quality, and competitive price.

When you compare pu sandwich panel options, you want to see how each manufacturer’s features stack up. You need to look at insulation values, fire resistance, soundproofing, customization, certifications, and after-sales support. These factors help you choose the right products for your project and maximize efficiency.

You get excellent thermal insulation from pu sandwich panels because of their closed-cell structure. This design creates a strong thermal barrier, which reduces heating and cooling costs. Many sandwich panel manufacturers treat their panels with fire retardants, so you benefit from improved fire resistance. You also enjoy good acoustic insulation, which makes your building quieter.

Here is a table that compares the main features of top pu sandwich panel manufacturers:

Manufacturer | Insulation (Thermal Conductivity) | Fire Resistance | Soundproofing (dB) | Customization Options | Certifications | After-Sales Support | pu sandwich panel price | pu sandwich panel machine factory |

|---|---|---|---|---|---|---|---|---|

Kingspan Group | 0.022 W/mK | Non-flammable | 30 | Wide range | ISO, CE, EN 13501-1 | Expert guidance, manuals | Competitive | Advanced, automated |

ArcelorMittal | 0.022 W/mK | Fire retardant | 30 | Flexible | ISO, CE | Global support | Competitive | Modern, large-scale |

Tata Steel | 0.022 W/mK | Fire retardant | 30 | Contemporary design | ISO, CE | Online/onsite support | Good value | Integrated, efficient |

Rautaruukki Corp. | 0.022 W/mK | Very good | 30 | Thickness, seals | LEED, BREEAM | Technical assistance | Value-focused | Innovative, precise |

Qatar Steel Company | 0.022 W/mK | Flame retardant | 30 | Moisture protection | ISO | Reliable service | Competitive | State-of-the-art |

Shanghai Sunnyda | 0.022 W/mK | Fire retardant | 30 | Color, size, joints | ISO9001, ISO14001 | High repeat order rate | Affordable | CNC, precision |

You should check certifications like ISO and CE before you buy. These show that the pu sandwich panel meets safety and quality standards.

You also want strong after-sales support. Some companies, like Kingspan and Tata Steel, offer expert guidance and technical help. Others, such as Shanghai Sunnyda, have a high repeat order rate, which means customers trust their service.

If you care about pu sandwich panel price, you will find that most manufacturers offer competitive rates. The pu sandwich panel machine in each factory affects quality and cost. Advanced production lines help keep prices low and ensure consistent products.

You can use this comparison to match the right pu sandwich panel to your needs. Look for the features that matter most for your project, and choose a manufacturer with strong support and reliable production.

You need to start by understanding your project’s unique needs before choosing a pu sandwich panel manufacturer. Look at factors that affect both cost and performance. For example, transportation costs can make up a large part of your total expenses. Choose a location with good highway access to save money. Make sure your site has the right utilities, such as electricity and water, so you do not need extra investment. Check the local labor market for skilled workers and training programs. Work with experienced engineers to design a facility that supports smooth material flow. Build a strong supply chain for raw materials and components. Finally, select equipment that matches your quality and efficiency goals.

Consideration | Description |

|---|---|

Transportation Costs | Significant portions of total product costs; consider locations with good highway access. |

Utility Requirements | Ensure sites can accommodate electrical, gas, water, and wastewater needs without extensive investment. |

Labor Availability | Evaluate local labor markets for skill levels, wage rates, and training program access. |

Facility Design | Optimize material flow and minimize handling costs; work with experienced engineers and architects. |

Supply Chain Development | Develop reliable supply chains for raw materials and components; evaluate suppliers carefully. |

Equipment Selection | Critical decision impacting product quality and efficiency; evaluate automation levels and capabilities. |

Once you know your project needs, match them with the features offered by each pu sandwich panel manufacturer. Some manufacturers provide panels with special core materials, such as rock wool or glass wool, to meet different insulation needs. Others adjust performance, like compressive strength, for harsh environments. You should also look at the pu sandwich panel machine each company uses. Advanced machines improve product consistency and efficiency. Request free samples to check quality and see if the products meet your standards.

Customization Type | Description |

|---|---|

Core Material Customization | Offers various core materials (rock wool, glass wool, etc.) tailored to specific insulation needs. |

Performance Customization | Adjusts properties like compressive strength based on environmental conditions (e.g., coastal areas). |

Free Sample Service | Provides free samples to evaluate quality and performance before making a decision. |

Tip: Always ask for technical support details. Good support helps you solve problems quickly and keeps your pu sandwich panel performing well.

You should compare all the information you have gathered. Look at the efficiency of each pu sandwich panel, the quality of after-sales support, and the flexibility of customization. Choose a manufacturer that offers reliable products, strong technical support, and a modern pu sandwich panel machine. This approach ensures your project runs smoothly and meets all safety and performance standards.

When you look for a reliable pu sandwich panel manufacturer, you should pay close attention to the machines and production lines they use. The right pu sandwich panel machine plays a key role in delivering consistent quality and high production capacity. Top manufacturers of pu sandwich panel machines invest in cutting-edge technology to stay ahead in the market.

Modern factories use advanced pu sandwich panel machines that bring many benefits:

Streamlined production processes boost efficiency and reduce the need for manual labor.

Enhanced precision and customization allow you to get panels that fit your exact project needs.

Energy efficiency and sustainability features help lower energy use and support eco-friendly goals.

Improved safety measures protect workers and reduce risks on the factory floor.

You will notice that versatile sandwich panel machines can handle different panel sizes, thicknesses, and core materials. This flexibility means you can order pu panels for many applications, from cold storage to modular buildings. High production capacity ensures that large orders get filled quickly, which keeps your project on schedule.

Factories with strong quality control systems check every panel for defects. This attention to detail helps you avoid costly mistakes and ensures long-lasting performance. When a pu sandwich panel manufacturer uses the latest technology, you benefit from better insulation, fire resistance, and soundproofing in every panel.

Note: Advanced machines also help keep costs down. Automated lines reduce waste and improve material use, which can lead to more competitive pricing for you.

If you want the best results, choose a manufacturer with a modern pu sandwich panel machine factory. You will get reliable products, fast delivery, and support for custom designs. This approach gives you peace of mind and helps you meet your project goals.

You have learned how to compare each PU sandwich panel manufacturer by quality, certifications, customization, and after-sales support. Match your project needs with the right manufacturer and product features.

Contact PU sandwich panel manufacturers directly.

Request technical data or visit a PU sandwich panel machine factory.

Making an informed choice helps you get the best PU sandwich panel price and ensures long-term project success.

You should look for consistent product quality, strong certifications, and advanced pu sandwich panel machine factory technology. Reliable manufacturers offer clear pu sandwich panel price information and provide excellent after-sales support. You get peace of mind and long-term value.

Tip: Always request technical data before you buy.

You can compare pu sandwich panel price by checking material quality, insulation values, and customization options. Ask each pu sandwich panel manufacturer for a detailed quote. Use a table to organize features and costs for easy comparison.

Manufacturer | Price | Insulation | Customization |

|---|---|---|---|

Kingspan | $$$ | High | Wide Range |

Sunnyda | $$ | Good | Flexible |

Advanced pu sandwich panel machine factory technology ensures you get panels with uniform quality, better insulation, and precise dimensions. You benefit from faster production and lower pu sandwich panel price. Modern machines also support eco-friendly manufacturing.

Most pu sandwich panel manufacturers offer customization. You can choose thickness, color, joint style, and core material. Customization affects pu sandwich panel price and production time. Always confirm options with the pu sandwich panel machine factory before ordering.

You should check for ISO, CE, and fire resistance certifications. These prove the pu sandwich panel manufacturer meets safety and quality standards. Certified panels from a trusted pu sandwich panel machine factory help you avoid compliance issues and ensure building safety.