Views: 89 Author: Site Editor Publish Time: 2025-10-27 Origin: Site

Are you scrambling to find cold room panels near me for your business? The right panels can make or break your cold room. If you choose wisely, you can see energy efficiency improve by up to 30%, which means lower bills and less spoilage in your cold storage unit. Take a look at how the right panels can impact your operation:

Impact Area | Effect |

|---|---|

Energy Efficiency | Improves by 20-30% |

Energy Costs | Directly reduces energy bills and carbon footprints |

Product Preservation | Reduces spoilage rates by up to 30% |

You want panels that protect your products and save you money. Let’s get started on finding the best fit.

Choosing the right cold room panels can improve energy efficiency by up to 30%, leading to lower bills and reduced spoilage.

Local suppliers offer faster delivery and support, making it easier to find the right cold room panels for your needs.

High-quality insulation materials like polyurethane (PU) provide better thermal performance, helping maintain stable temperatures in cold storage.

Always check for certifications to ensure your cold room panels meet safety and compliance standards for food and pharmaceutical storage.

Assess your specific business needs, including temperature requirements and safety regulations, before selecting cold room panels.

Looking for cold room panels near me can feel overwhelming, but you have several ways to make your search easier and faster. Let’s break down your options so you can find the right panels for your cold storage needs.

Start by checking local suppliers in your area. Many businesses use online directories to find cold room panel suppliers close by. These directories list companies that specialize in cold storage solutions. Here’s a quick look at some popular options:

Supplier Name | Description |

|---|---|

ThomasNet | A directory of insulated cold storage panel manufacturers and suppliers across the USA and Canada, providing instant quotes and product catalogs. |

Barr Inc. | Offers customizable insulated cold storage panels with various configurations, ready to ship, and includes installation trim necessary for assembly. |

Local suppliers often know the climate and regulations in your region. You can get faster delivery and sometimes even on-site support for your cold room project.

When you search for cold room panels near me online, use specific keywords like “cold storage panels” or “cold room panel suppliers.” This helps you find companies that serve your area. Try using search engines, business directories, and even manufacturer locators. You can also check out platforms like:

Supplier Name | Location | Description |

|---|---|---|

Polar King International | Fort Wayne, IN | Manufacturer of cold rooms and controlled environmental rooms for medical and pharmaceutical industries. |

Panel Built, Inc. | Blairsville, GA | Manufacturer of cold storage and cooling environmental rooms with various features. |

Mezzmaster.com | Mount Laurel, NJ | System integrator for cold storage rooms, offering consulting and project management services. |

Tip: Cold room panels provide superior thermal efficiency. They work well for food and pharmaceutical industries. Look for features like freeze-thaw resistance and non-corrosive materials.

You can also go straight to the source. Many cold room panel manufacturers offer direct sales. This gives you more choices for customization and better pricing. Manufacturers often provide expert advice on which panels fit your cold storage needs best. You can ask about installation, warranties, and after-sales support. Dealing directly with a manufacturer can help you get the most value for your cold room panels near me search.

When you choose cold storage panels, you want to know what makes them work best for temperature-controlled environments. Let’s break down the features that matter most for your business.

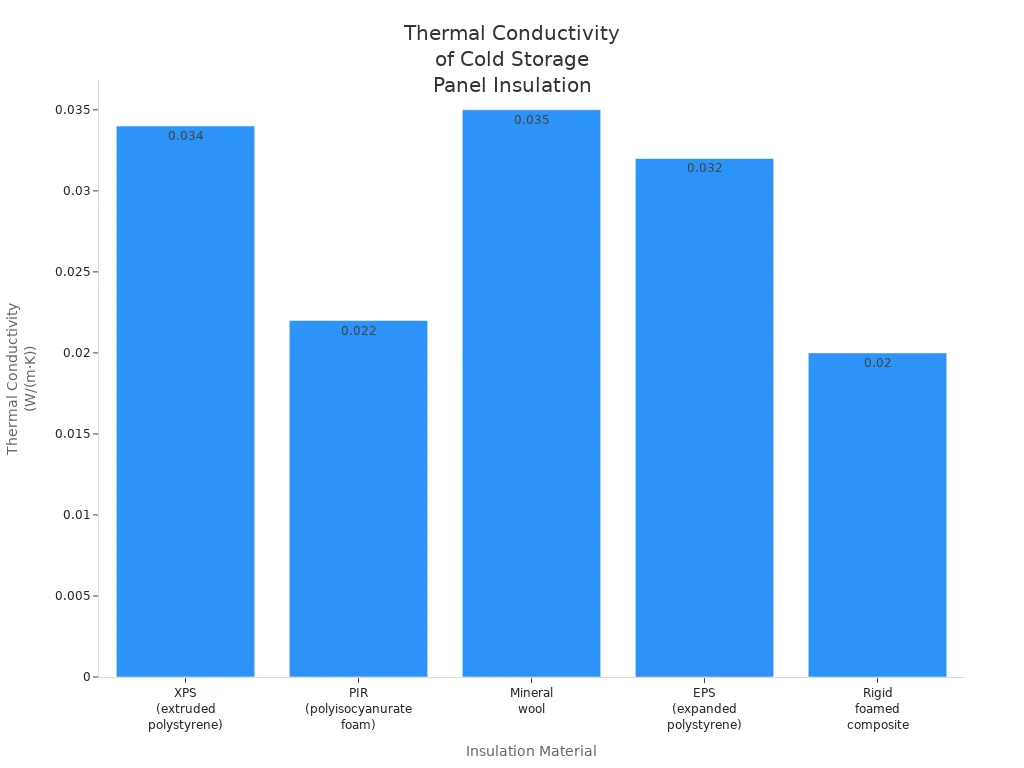

Insulation is the heart of any cold storage panel. You need panels that keep perishable goods safe and maintain stable temperatures. The most common insulation materials include EPS (expanded polystyrene), PU (polyurethane), PIR (polyisocyanurate), XPS (extruded polystyrene), mineral wool, and rigid foamed composites. Each material offers different thermal properties, which affect how well your cold storage performs.

Here’s a quick comparison of thermal conductivity values:

Insulation Material | Thermal Conductivity (λD) [W/(m·K)] |

|---|---|

XPS (extruded polystyrene) | 0.034 |

PIR (polyisocyanurate foam) | 0.022 |

Mineral wool | 0.035 |

EPS (expanded polystyrene) | 0.032 |

Rigid foamed composite | 0.020 |

Lower thermal conductivity means better insulation. Rigid foamed composite and PIR panels offer top thermal performance, which helps you keep your temperature-controlled environments stable and energy costs low. If you need custom features, ask your supplier about options for different insulation panels.

Thickness matters just as much as insulation type. The right thickness keeps your cold storage efficient and safe. For food storage, you want panels that match your application:

Application Type | Recommended Thickness (mm) |

|---|---|

Chilling | 80 |

Freezing | 100 - 140 |

Ultra-Freezing | 150 - 200 |

If you run a refrigeration room, you’ll need 80–100 mm panels to keep temperatures between 0°C and +10°C. Freezing rooms need 120–150 mm panels for -18°C to -25°C. Ultra-low temperature rooms require 150–200 mm panels to maintain -25°C to -40°C.

Cold Storage Type | Temperature Range | Recommended Thickness |

|---|---|---|

Refrigeration Room | 0°C to +10°C | 80–100 mm |

Freezing Room | -18°C to -25°C | 120–150 mm |

Ultra-Low Temperature Room | -25°C to -40°C | 150–200 mm |

Thicker panels mean better thermal stability and less energy loss. You protect perishable goods and keep your cold storage running smoothly.

You want cold storage panels that save energy and money. High-efficiency insulation panels use materials like polyurethane foam or polystyrene. These panels minimize heat transfer, so your temperature-controlled environments stay stable without using extra energy.

Cold storage panels are prefabricated and insulated for excellent thermal performance.

Materials like PU and polystyrene boost insulation efficiency and lower energy consumption.

These panels keep temperatures steady, so you don’t waste energy like you would with older systems.

If you upgrade to high-efficiency panels, you can see a payback period of just 2 to 5 years. That means your investment pays off quickly, thanks to lower energy bills and better temperature control.

Tip: Ask your cold storage panel suppliers about energy ratings and thermal performance data before you buy. This helps you choose panels that deliver real savings.

Safety and compliance are critical for any cold storage project. You need panels that meet food safety standards and local building codes. Look for certifications like ISO, HACCP, FDA, and EU food safety compliance. These standards ensure your panels are safe for food storage and meet industry regulations.

Common compliance issues include:

Understanding local building codes

Meeting health and safety regulations

Following industry-specific standards

Insulation types affect compliance, too. Materials like PU, PIR, and EPS have different thermal and fire resistance ratings. You must choose panels that meet regional codes for fire safety and moisture resistance. This keeps your cold storage facility safe and efficient.

Note: Always check with your cold room panel manufacturers or suppliers to confirm that their panels meet all required certifications and safety standards.

When you focus on the right features—insulation, thickness, energy efficiency, and compliance—you build a cold storage solution that protects your products, saves money, and meets all safety requirements.

Choosing the right thermal panels for your cold storage unit can feel like a big decision. You want panels that fit your business, keep your products safe, and help you save money over time. Let’s walk through how to choose thermal panels that match your needs.

Before you pick any panels, take a close look at your cold storage unit and what you need it to do. Every business has different requirements, so you want to match your panels to your operation. Start by asking yourself these questions:

What is the size of your cold room?

What temperature range do you need to maintain?

Will you store food, medicine, or other sensitive products?

Do you have specific safety or hygiene requirements?

How important is energy efficiency for your business?

You can use this table to help you compare the main factors:

Factor | Description |

|---|---|

Insulation Core Materials | Types include PUR, PIR, EPS, and rock wool, each with different thermal properties. |

Panel Thickness | Affects insulation efficiency and cost; thicker panels generally provide better insulation. |

Surface Material and Coating | Determines durability and hygiene; options include galvanized steel, stainless steel, and aluminum. |

Fire Safety Requirements | Important for compliance; different materials have varying fire resistance ratings. |

Moisture and Vapor Resistance | Essential to prevent mold and degradation; sealed joints and vapor barriers are critical. |

Joint System and Installation | Affects structural integrity and thermal performance; choose systems that suit project needs. |

Compliance and Certification | Ensure panels meet relevant standards for safety and performance. |

Environmental Considerations | Focus on sustainability and energy efficiency in material selection. |

Cost vs. Performance Trade-Off | Balance budget constraints with operational needs and long-term savings. |

You want to make sure your cold storage unit meets all safety and compliance requirements. The right thermal panels help you keep the temperature range steady, protect your products, and avoid costly repairs.

Tip: Always check the temperature range you need before you buy. The wrong panel thickness or insulation can lead to higher energy bills and spoilage.

When you look at how to choose thermal panels, you’ll see two main options: EPS (expanded polystyrene) and PU (polyurethane). Each type has its own strengths and weaknesses. Your choice depends on your cold storage unit’s temperature range, your budget, and how long you want the panels to last.

Here’s a quick comparison:

Feature | PU Panels | EPS Panels |

|---|---|---|

Insulation | Superior thermal insulation with low thermal conductivity | Good thermal insulation, but less effective than PU |

Durability | Exceptional durability and moisture resistance | More vulnerable to physical damage |

Cost | Generally more expensive | Most cost-effective option |

Energy Efficiency | Helps maintain stable temperatures, reducing energy consumption | Lower thermal efficiency, leading to higher energy use over time |

Fire Risk | Less flammable than EPS | More flammable than PU |

PU panels give you better thermal performance and last longer. They keep your cold storage unit at the right temperature range with less energy. You might pay more upfront, but you save money on energy bills and repairs. PU panels can last over 25-30 years if you take care of them. EPS panels cost less and work well for basic cold room needs, but they don’t insulate as well and may not last as long. Most cold rooms with EPS panels last between 5 and 20 years, depending on use and care.

If you need a cold storage unit for sensitive products or strict temperature range control, PU panels are a smart choice. If you want a budget-friendly solution for a standard cold room, EPS panels can work, but you may need to replace them sooner.

Your budget plays a big role in how to choose thermal panels. You want to balance cost with performance and safety. Here’s a table to help you compare the average costs and features:

Panel Type | Cost Comparison | Thermal Insulation (λ value) | Structural Strength | Fire Rating |

|---|---|---|---|---|

Polyurethane (PU/PIR) | Most expensive | 0.021-0.023 W/mK | Excellent | Higher |

Expanded Polystyrene (EPS) | Least expensive | 0.033-0.038 W/mK | Lower | Lower |

PU panels cost more, but they give you better thermal insulation and structural strength. They also have a higher fire rating, which means better safety for your cold storage unit. EPS panels save you money upfront, but you may spend more on energy and maintenance over time.

PU panels: Higher initial cost, lower long-term energy bills, longer lifespan.

EPS panels: Lower initial cost, higher energy use, shorter lifespan.

Note: Think about your long-term needs. Spending a bit more now on better thermal panels can save you money and hassle down the road.

When you decide how to choose thermal panels, look at your cold storage unit’s temperature range, your safety requirements, and your budget. The right panels help you keep your products safe, your energy bills low, and your cold room running smoothly for years.

Choosing the right supplier for your cold storage project can make a huge difference in performance and peace of mind. You want a partner who delivers quality, reliability, and strong support. Here’s how you can evaluate cold room panel suppliers with confidence.

Start by checking what other customers say. Reviews and testimonials give you real insight into how suppliers handle orders, installation, and after-sales service. Look for suppliers with a solid market reputation and positive feedback about their thermal panels. You can also ask for references from recent projects. This helps you see if the supplier delivers on promises and stands behind their products.

Here’s a quick table to help you compare key criteria:

Criteria | Description |

|---|---|

Product Quality | Durable materials and high thermal efficiency for long-term cold storage performance. |

Innovation | Advanced technology and design that improve thermal performance and appeal. |

Certifications | Industry and environmental certifications for quality and sustainability. |

Market Reputation | Customer reviews and industry awards that show reliability and trust. |

Tip: Always check for suppliers who have experience with cold storage and can provide proof of successful installations.

Certifications show that a supplier takes safety and quality seriously. When you choose a supplier, look for these important certifications:

CE Certification: Meets European safety standards for performance and durability.

UL Certification: Proves the panels meet strict safety requirements for insulated systems.

FM 4880: Offers a Class 1 fire resistance rating, which is crucial for safety.

NSF Certification: Confirms the panels are safe for commercial use.

ETL Certification: Validates electrical safety and quality control.

Fire Certifications: Ensures the panels resist fire propagation.

Energy Certifications: Confirms compliance with energy efficiency codes.

BRC Global Standards Certification: Guarantees food safety and quality.

IFS Certification: Shows compliance with agri-food market safety standards.

These certifications help you trust that the thermal panels will perform well and keep your cold storage safe.

Great service and support can save you time and money. Leading cold room panel suppliers offer flexible repairs, expert teams, and on-site customization. They can handle complex repairs and make sure replacements fit perfectly, keeping your thermal system efficient. Some suppliers even add new components that work smoothly with your current setup, so you avoid downtime.

Here’s what you should expect:

Service Aspect | Description |

|---|---|

Flexibility in Repairs | Custom solutions for repairs, replacements, and additions. |

Expert Team | Skilled professionals who handle complex thermal repairs efficiently. |

On-Site Customization | Ability to adapt panels and doors to unique cold storage challenges. |

Precision in Repairs | Ensures replacements match your existing thermal setup for best performance. |

Integration of New Components | Adds new features that blend with your current cold storage system, minimizing disruption. |

Note: Reliable service and support mean you get the most out of your thermal panels and keep your cold storage running smoothly.

You can find the best cold room panels near you by following a simple checklist. Start by defining your performance needs, then check insulation quality, compliance, and supplier reputation. Here’s a quick guide:

Step | What to Do |

|---|---|

1 | List your temperature and safety needs. |

2 | Choose high-quality insulation. |

3 | Verify certifications and reviews. |

Avoid common mistakes like poor planning or ignoring energy efficiency. Reach out to local cold room panel suppliers or cold room panel manufacturers today to get the right panels for your business.

You get faster delivery, local support, and panels that fit your climate. Local suppliers often know your area’s building codes. This helps you set up your cold room quickly and keeps your cold storage unit running smoothly.

Think about what you store and the temperature you need. Thicker panels work better for freezing or ultra-low temperatures. Ask your supplier for advice based on your cold storage unit’s needs.

Some panels are easy to install, but you might need a pro for larger cold rooms. Professional installation ensures your cold storage unit stays energy efficient and safe.

Check for certifications like ISO or FDA. Ask your supplier for proof. Certified panels help you meet health and safety rules for your cold storage unit.

Start with online directories or search engines. Look for trusted cold room panel suppliers in your area. You can also contact cold room panel manufacturers for direct options.