Views: 58 Author: Site Editor Publish Time: 2025-12-01 Origin: Site

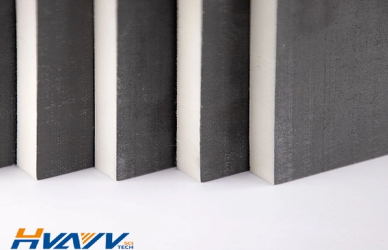

Proper cutting and handling of polyiso board are essential steps in ensuring a successful insulation installation. Incorrect techniques can damage the boards, reducing their thermal performance and compromising the building’s energy efficiency. By following correct procedures, installers can preserve the board’s integrity, enhance safety on-site, and achieve optimal insulation results. This article outlines the key benefits of proper cutting and handling to help professionals maintain the quality and effectiveness of polyiso insulation throughout the construction process.

To achieve clean and precise cuts on polyiso boards, it is important to use the right tools. Utility knives with sharp blades are ideal for making straight cuts on thinner boards. For thicker or larger panels, hand saws or specialized insulation cutting saws provide better control and accuracy. Electric hot wire cutters can also be used for smooth, dust-free cuts, especially in professional settings.

When cutting polyiso boards, safety should always be a priority. Wearing protective gloves helps prevent cuts and abrasions from sharp edges or tools. Safety goggles protect eyes from dust and small debris generated during cutting. Additionally, wearing a dust mask or respirator is advisable to avoid inhaling fine particles, especially when cutting large quantities or working in enclosed spaces. Proper safety gear ensures a safer working environment while maintaining cutting precision.

Before starting to cut polyiso boards, it is essential to prepare a clean and flat work surface. A stable and even surface ensures precise, straight cuts and prevents the board from shifting during cutting, which can cause uneven edges or damage. Remove any debris, dust, or obstacles from the area to maintain safety and efficiency.

Good lighting is crucial for accurately marking and cutting polyiso boards, allowing installers to see measurements and cut lines clearly. Additionally, proper ventilation helps disperse any dust or fumes generated during cutting, creating a healthier work environment. Ensuring both adequate lighting and ventilation contributes to safe and effective handling of polyiso boards on-site.

Accurate measurement and marking are crucial for achieving precise cuts on polyiso boards. Use a reliable measuring tape and a straightedge or T-square to mark cut lines clearly. Double-check measurements before cutting to avoid errors that can lead to material waste or improper fit during installation.

1.Place the polyiso board on a clean, flat surface, ensuring it is fully supported.

2.Align your cutting tool along the marked line, applying steady and even pressure.

3.For thinner boards, score the surface with a utility knife, then snap the board along the scored line for a clean break.

4.For thicker panels, use a saw or hot wire cutter, making slow and controlled cuts to prevent rough edges or crumbling.

5.Smooth any rough edges with sandpaper or a rasp if necessary to ensure a perfect fit.

To reduce dust generation, cut slowly and avoid aggressive sawing motions. Using a cutting tool with dust extraction or working outdoors can also help control airborne particles. Wearing a dust mask and eye protection further safeguards health during cutting. Keeping the work area clean by regularly sweeping or vacuuming helps maintain a safe and efficient workspace.

When handling polyiso boards, it is important to use proper lifting techniques to prevent damage to the boards and reduce the risk of injury. Always lift with your legs rather than your back, keeping the board close to your body for better control and balance. Avoid sudden movements or dropping the boards, as impacts can cause cracks or dents that compromise insulation performance.

Polyiso boards are rigid and can be susceptible to bending or cracking if mishandled. Handle the boards gently and avoid applying excessive force or twisting motions. Be especially cautious around edges and corners, which are more prone to chipping. Storing and transporting the boards flat helps maintain their structural integrity.

For larger or thicker polyiso panels, it is recommended to have two people perform the lift and carry. Coordinated teamwork ensures even support, reducing the risk of bending or dropping the board. Two-person lifts also improve safety for workers by distributing the load and preventing strain injuries during handling.

When transporting cut polyiso boards on-site, it is essential to handle them carefully to avoid damage. Use flatbed carts, dollies, or pallets to move multiple boards efficiently and reduce direct handling. Carry boards horizontally with firm support along their length to prevent bending or snapping. Avoid dragging boards across rough surfaces to protect their integrity.

Edges and surfaces of polyiso boards are vulnerable to chipping and abrasion. To safeguard them during transport, stack boards with protective layers such as foam sheets or cardboard between each layer. Secure the load with straps or ropes to prevent shifting or falling during movement. If transporting outdoors, cover the boards with waterproof tarps to shield against moisture and dirt. These precautions help maintain the boards’ quality until installation.

Uneven or rough cuts can compromise the fit and performance of polyiso boards. To avoid this, always use sharp, high-quality cutting tools and ensure accurate measuring and marking before cutting. If a cut ends up uneven, smooth the edges gently with sandpaper or a rasp to improve fit. Taking time to cut carefully minimizes gaps and ensures a professional finish.

Polyiso board edges are particularly prone to cracking or chipping if mishandled. Support the board fully when lifting or moving, and avoid applying pressure directly on the edges. Use protective edge guards or padding during transport and storage to reduce impact damage. When working near edges, use gentle, steady movements to preserve board integrity.

Working in confined or awkward areas can increase the risk of damaging polyiso boards and causing injury. Plan cuts and handling steps in advance to minimize movement in tight spots. Use smaller, manageable board sections where possible and employ proper personal protective equipment (PPE). Maintaining clear communication with team members and ensuring adequate lighting can also improve safety and efficiency in challenging environments.

Proper cutting and handling of polyiso boards are essential to ensure their insulation performance and durability. By using the right tools, preparing the work area carefully, following precise cutting techniques, and practicing safe handling and transport methods, installers can achieve clean, accurate installations that maximize energy efficiency and longevity. Adhering to these best practices not only protects the material but also contributes to overall project success and safety.

For more detailed information and high-quality polyiso insulation products, we recommend visiting Huayu New Tech (Beijing) International Trade Co., Ltd. Their expertise and reliable solutions can help you achieve the best results in your insulation projects. Feel free to contact them to learn more about their offerings and professional support.