Views: 0 Author: Site Editor Publish Time: 2025-06-09 Origin: Site

You might ask if duct board insulation is the best for your HVAC system. Many people pick it because it saves a lot of energy. If you insulate your duct, you can save up to 30% on energy bills. The table below shows how much insulation your duct should have:

HVAC Component | Recommended Insulation Level (R-Value) |

|---|---|

Ductwork in Unconditioned Spaces | R-6 to R-8 |

Ductwork in Conditioned Spaces | R-4 to R-6 |

Pipes | R-3 to R-6 |

Think about how it works, how much it costs, how easy it is to put in, how long it lasts, how much energy it saves, health, safety, and where you will use it. The best choice depends on what you need.

Duct board insulation can help save up to 30% on energy bills. It keeps the air in the ducts at the right temperature. It is cost-effective and easy to install. This makes it a good choice for straight ducts in homes, schools, and offices. This insulation controls moisture well. It helps stop mold and keeps your duct system clean and safe. Duct board helps lower noise from HVAC systems. This makes indoor spaces quieter and more comfortable. It meets important safety standards. It resists fire, mold, and fiber release. This helps protect your health and home. Regular inspection and maintenance keep duct board insulation working well. This also helps protect indoor air quality. Duct board is less flexible and can be fragile. But it is durable if you handle it with care. Experts and users agree that duct board insulation is a good balance. It saves energy, is safe, and is easy to use for many HVAC projects.

When you pick insulation, energy efficiency is very important. Good insulation keeps warm or cool air inside the duct. This helps your HVAC system not work as hard. You use less energy and save money. The table below shows how insulation helps:

Metric | Before Insulation | After Insulation | Improvement/Impact |

|---|---|---|---|

Thermal Transmittance (U-value) | 1.47 W/m²K | 0.38 W/m²K | Less heat escapes through ducts |

Air Leakage Rate | 606.4 changes/hr | 11.0 changes/hr | Ducts keep air inside much better |

Energy Consumption | 190.7 kWh/m² | 135.1 kWh/m² | 29% less energy used |

Adding insulation can lower energy use by almost one-third. This means your bills go down. Your HVAC system does not have to work as hard. Using the right insulation thickness saves $10 to $26 per square meter each year. The money you spend comes back in two to four years. You also help the planet by lowering greenhouse gas emissions by up to 80%.

Cost is important when you choose duct insulation. You want to pay a fair price now and save money later. Some types, like spray foam, cost more at first but save more energy. Others, like fiberglass, cost less and still work well. The table below shows what to look for:

Criteria for Best Insulation Option | Explanation |

|---|---|

R-value (Thermal Resistance) | Higher R-value means better insulation and more savings. |

Air Leakage Reduction | Less air leaks mean lower energy bills. |

Moisture Resistance | Keeps insulation working longer, so you do not have to replace it often. |

Environmental Impact | Some insulation types are better for the planet. |

Think about how long it takes to get your money back. Most insulation pays for itself in a few years. After that, you keep saving money every year.

How you install insulation matters a lot. Some types, like fiberglass boards, are easy to put in. Others, like spray foam, need special tools and skills. If you install insulation the right way, you save more energy. Bad installation wastes money and energy.

Tip: Make sure your insulation fits your duct and HVAC system. If it does not fit, you lose energy and comfort.

Pick insulation that resists moisture and mold. This keeps your duct system safe and healthy. Some materials, like mineral wool, also help with fire safety and noise. When you choose insulation, think about how easy it is to install, how long it lasts, and how well it protects your duct.

When you pick insulation, you want it to last a long time. Durability means the material keeps working for many years. Some types, like insulated metal panels, last 40 to 60 years. They can handle bad weather, strong winds, and heavy rain. You do not need to fix or change them often. This saves you both money and time.

Insulated metal panels do not get damaged by sun or water.

They stay in shape and do not fall apart easily.

You only need to check and clean them once each year.

Other insulation, like acrylic or lime-based systems, may not last as long. Some can get moldy or soak up water, especially in wet places. This makes them work less well over time. Silicate-based insulation does not get moldy, but it can hold more water and let less air move through. This can cause water to build up inside your duct.

Tip: Choose insulation that fits your weather and building needs. If you live where it rains or is windy, pick a material that keeps out water and stands up to weather.

Strong insulation helps your duct last longer. It also keeps your HVAC system working well. When you use tough insulation, you help the planet by making less waste and saving energy.

Air quality is important for your health and comfort. Some insulation can let out chemicals called VOCs. These can make the air in your home less healthy. You want insulation that keeps the air clean.

A study looked at different insulation types and found some let out more VOCs. Hemp insulation lets out very few VOCs. This makes it a good pick if you care about indoor air. Other materials, like some foams or fiberglass, may let out more chemicals, especially when new.

Low-VOC insulation helps people with allergies or asthma.

It keeps the air in your duct system clean and safe.

You breathe easier and feel better in your space.

Note: Always ask about VOC levels when you choose insulation. Look for products tested for indoor air safety.

Good insulation saves energy and protects your health. When you pick the right material, you get comfort and peace of mind.

Noise can move through your duct system and bother you. Insulation helps block or soak up sound, making your home quieter. The NRC shows how well a material soaks up sound. A higher NRC means better noise control.

Many insulation products, like acoustic panels or ceiling tiles, use NRC ratings.

Not all insulation blocks noise the same way.

Some materials work better for certain sounds.

A study in Turkey showed some insulation cuts noise well, but others do not. The best choice depends on where you use it and what noise you want to stop.

Tip: If you want a quiet space, pick insulation with a high NRC. This helps keep unwanted sounds out of your rooms.

Insulation in your duct system can lower noise a lot. You get a more peaceful place and better comfort.

When you choose insulation for your HVAC system, safety should always come first. You want to protect your home and everyone inside. Duct board insulation stands out because it keeps you safe in several ways.

Manufacturers test duct board insulation under tough conditions. They run air through it at speeds much higher than what you find in most homes. These tests show that duct board insulation does not break down or release fibers into the air. In fact, tests using special microscopes found no glass fibers in the air after seven hours of use. The fiber levels stayed below what you find outside. This means you do not have to worry about breathing in harmful particles.

Good insulation helps keep your air clean and safe to breathe.

Duct board insulation also resists fire. It meets strict safety standards, so it does not catch fire easily. This gives you peace of mind, especially if you live in a place where fire safety matters. The material also stands up to heat, cold, and moisture. It does not rust or grow mold. When you keep moisture out, you stop mold and mildew from growing. This protects your health and keeps your air fresh.

Here are some key safety features to look for in insulation:

Fire resistance: Stops flames from spreading.

Mold and mildew control: Keeps your air healthy.

No fiber release: Prevents breathing problems.

Strong against heat and cold: Lasts longer and stays safe.

You should also think about safety during installation. Pick insulation that does not give off toxic fumes. Make sure you or your installer wear the right gear. Good ventilation helps if you use sealants. After you install it, check your insulation often. Look for damage or signs of wear. This keeps your system safe and working well.

A safe insulation choice protects your family, your home, and your health. Duct board insulation gives you strong safety features that last for years.

Duct board insulation uses hard panels made from fiberglass or mineral wool. These panels look like thick boards. The inside is dense and traps air. This slows down heat moving through the duct. The outside has a foil or mat layer. This layer keeps out water and makes the board stronger. You can cut or shape duct board to fit many duct sizes.

Fiberglass duct insulation is strong and flexible. You can bend it for corners or cut it for straight parts. The surface does not get damaged by air moving inside. Duct board gives you insulation already built in. You do not need to add more layers.

Note: Duct board panels follow strict ASTM rules for heat and sound. This means you can trust how they work every time.

Duct board insulation keeps hot or cold air inside the duct. It blocks outside temperatures from getting in. The r-value shows how well it works. Most duct board has an r-value from R-4 to R-8. This range works for most HVAC jobs.

Duct board also helps with noise. The glass core soaks up sound as air moves. This makes rooms quieter. Studies show duct board insulation cuts heat loss and noise. It also stops water from forming on ducts. Keeping out water protects your duct from mold and damage.

Here are some main features of duct board insulation:

Keeps a high r-value for many years

Stops air leaks and saves energy

Controls water on duct surfaces

Meets safety and efficiency codes

You can use checklists to see if your duct board is installed right. These lists help you find gaps or weak spots that could hurt performance.

You can use duct board insulation in many places. It works for new buildings and upgrades. You see it in homes, schools, and offices. It fits best where you have straight runs or simple shapes. You can use it for supply and return ducts in spaces without heating or cooling.

Duct board is good when you want built-in insulation and easy setup. You can install it fast because it comes in big panels. It helps when you need to follow energy codes or want better indoor air. Fiberglass duct insulation is great for projects that need good heat control and less noise.

Application Area | Why Use Duct Board? |

|---|---|

Residential Homes | Easy to install, saves energy |

Schools and Offices | Reduces noise, improves air quality |

Commercial Buildings | Meets code, controls condensation |

Tip: Pick duct board if you want to save energy, have quiet rooms, and install it easily.

When you choose duct board insulation, you get several strong benefits. This material gives you built-in insulation, so you do not need to add extra layers. You save time and effort during installation. The panels fit together easily. You can cut them to match the shape of your duct. This makes the job faster and less messy.

You also save money. Duct board insulation costs less than some other options. You do not need special tools or skills to install it. Many people can handle the job themselves. This lowers your labor costs.

Moisture control is another big plus. The outer layer blocks water and keeps the inside dry. This helps stop mold and mildew from growing. Your duct stays clean and safe for longer.

You get less air leakage, too. The panels seal tightly. Air stays inside the duct and does not escape. Your HVAC system works better and uses less energy. You see lower bills each month.

Noise reduction is a hidden bonus. The thick panels soak up sound. You hear less noise from your HVAC system. Your home or office feels quieter and more comfortable.

Here is a quick look at the main advantages:

Advantage | What It Means for You |

|---|---|

Built-in insulation | No extra layers needed |

Cost-effective | Lower material and labor costs |

Moisture control | Less risk of mold and mildew |

Reduced air leakage | Better energy savings |

Easy installation | Simple tools, quick setup |

Noise reduction | Quieter indoor spaces |

Tip: If you want a simple, affordable way to insulate your duct, duct board insulation gives you strong results.

You should also know the downsides before you decide. Duct board insulation can have problems with fiber erosion. Over time, small fibers may break loose inside the duct. These fibers can move through your air system. Some people worry about breathing them in, especially if they have allergies.

Air quality concerns may come up. If the panels get damaged, they can release fibers or dust. You need to check your duct for signs of wear. If you see damage, you may need to repair or replace the insulation.

This material is not very flexible. You may find it hard to use duct board insulation on curved or tight spaces. The panels work best on straight runs. If your duct bends a lot, you may need a different type of insulation.

Fragility is another issue. The panels can crack or break if you handle them roughly. You must take care during installation. If you drop a panel, it may not work as well.

Over time, duct board insulation can degrade. Moisture, heat, or pests can damage the panels. If this happens, the insulation may not protect your duct as well. You may need to check it every year to make sure it still works.

Here is a table to help you see the main disadvantages:

Disadvantage | What to Watch Out For |

|---|---|

Fiber erosion | Possible air quality issues |

Air quality concerns | Dust or fibers in the air |

Limited flexibility | Hard to use on curves or tight spots |

Fragility | Panels can crack or break |

Degradation over time | May need repairs or replacement |

Note: Always inspect your duct board insulation after installation. Regular checks help you catch problems early and keep your air safe.

Many HVAC ducts have duct liner insulation inside. This insulation covers the inside walls of the duct. It is usually made from soft fiberglass or foam. You can use duct liner in both new and old HVAC systems. It works for straight ducts and for bends.

Duct liner helps lower noise. It soaks up sound as air moves through. This makes your home or office quieter. Builders often use duct liner to meet sound rules. It also helps keep the air in your duct at the right temperature. Your HVAC system does not have to work as hard.

Duct liner comes in rolls or boards. You cut it to fit your duct. You stick it on with special glue. The surface is smooth, so it is easy to clean. This helps stop dust from building up.

Here are some important facts about duct liner insulation:

You can use it with air speeds up to 6,000 feet per minute.

It works in temperatures up to 250°F.

It is not for kitchen exhaust ducts or greasy places.

You can clean it with a vacuum or air wash.

Duct liner insulation helps with indoor air quality. Many types have low VOCs. They meet strict health and safety rules. You can check safety sheets for more information.

Performance Aspect | Details / Standards / Metrics |

|---|---|

Fire Resistance | ASTM E84/UL723, CAN/ULC-S102 |

Acoustic Performance | ASTM C423/E795 - Sound Absorption Coefficient (SAC), Noise Reduction Coefficient (NRC), Sound Insertion Loss |

Thermal Performance | ASTM C177, C518, C1114 - Thermal Conductivity and Heat Flow Limitation; ASTM C411 - Service Temperature |

Moisture Control | ASTM C1104 - Water Vapor Sorption |

Acoustic Function | Reduces sound transmission in HVAC systems, improving Indoor Environment Quality (IEQ) acoustics segment |

Thermal Function | Retards heat gain/loss for energy savings, condensation control, and thermal comfort (IEQ thermal segment) |

Combined Insulation Use | Example: 1" duct liner (R-4.2) + external wrap (R-3.8+) to meet R-8 thermal insulation efficiently |

Velocity & Temperature | Suitable for air velocities up to 6,000 ft/min; max service temperature 250°F; not for kitchen exhaust or similar |

Forms | Blanket rolls (various thicknesses), rigid boards (for plenums) |

Acoustic Noise Types | Crosstalk, Insertion, System-borne noises |

Acoustic Measurement | SAC (sound energy absorbed), NRC (average SAC), Sound Insertion Loss (dB reduction) |

Density vs Thickness | Thickness increase generally more effective than density increase for sound attenuation, frequency dependent |

Installation | Blanket liners applied manually or automatically; rigid liners applied manually |

Maintenance | Cleaning methods: Contact vacuuming, Air washing, Power brushing; designed for durability and cleaning |

You can use duct liner and duct wrap together for higher R-values. For example, use a 1-inch duct liner (R-4.2) and add duct wrap (R-3.8+) to reach R-8. This helps you follow energy rules and save money.

Tip: Always check if your duct liner meets fire and air quality rules. This keeps your system safe and healthy.

Rigid foam board is another way to insulate your duct. You put it on the outside of the duct, like duct wrap. It comes in big panels. You cut and fit these panels around your duct. You may need to seal the edges with tape or caulk.

There are different types of rigid foam board:

Expanded Polystyrene (EPS): It costs less but does not insulate as well. You use it in dry places.

Extruded Polystyrene (XPS): It costs more but keeps out water better. It works in wet areas.

Polyisocyanurate (Polyiso): It gives the highest R-value. It costs the most. It may not work well in wet places.

Expanded Polyurethane (EPU): It is strong and lasts a long time. You see it in special building jobs.

You might also see mineral wool boards. These do not burn and keep out water. They cost more than fiberglass.

Aspect | Rigid Foam Board Insulation | Fiberglass Insulation (Duct Board Alternative) |

|---|---|---|

Cost (for R-15, 10 sq ft) | Approximately $10 | Approximately $3.40 to $4.00 |

Durability | Lasts 80 to 100 years; more resistant to water and pests; requires careful fitting and sealing | Lasts 80 to 100 years but prone to water damage, mold, and pest contamination; must be replaced if damaged |

Moisture Resistance | More moisture resistant; higher-density foam recommended for wet areas | Not water resistant; susceptible to mold and rot |

Installation | Requires cutting to fit obstructions; may need caulking for gaps; clean and irritant-free | Flexible to fit around obstructions; irritant to skin and lungs; requires protective gear |

Waste | Produces unusable small pieces when cut | Produces less waste; can be torn and tucked into small areas |

Vapor Barrier | Foil-faced foam acts as vapor barrier; non-foil may need additional vapor barrier | Vapor-retarding facing may eliminate need for separate vapor barrier |

Rigid foam board keeps out water better than fiberglass duct wrap. It lasts longer and keeps out bugs. You may pay more at first, but you save on repairs.

Note: Always seal the joints and edges of foam board. This stops air leaks and keeps your duct system working well.

Spray foam is a flexible way to insulate your duct. You spray it right onto the duct. It grows and fills every gap. You get a tight seal with no air leaks. Spray foam works for odd shapes and hard-to-reach spots.

You can use spray foam inside or outside the duct. Most people use it on the outside, like duct wrap. It sticks to metal, plastic, or other surfaces. You do not need to cut or fit panels.

Spray foam gives you a high R-value for each inch. It blocks air and water. You get strong insulation and a vapor barrier at the same time. Spray foam costs more than duct liner or duct wrap. You need special tools and safety gear to use it.

Here are some reasons to pick spray foam:

It fills every gap and crack.

It stops air leaks better than most duct wrap.

It keeps out water and mold.

It lasts a long time and needs little care.

Spray foam is good for ducts in tight spaces or with lots of bends. It works well when you need a custom fit.

Tip: Always hire a trained pro for spray foam jobs. This keeps your duct safe and your air clean.

Metal ducts are common in new HVAC systems. Adding a lining makes them work better. The lining goes inside the metal duct. It is made from fiberglass or elastomeric foam. This lining helps control temperature, noise, and air quality.

A lined metal duct keeps air at the right temperature. The lining stops heat from escaping. This means your HVAC system uses less energy. Fiberglass linings trap heat or cold inside the duct. Your system does not run as long to keep you comfortable. This saves you money on energy bills. Elastomeric foam linings stop water drops from forming. They also protect the metal from rust. Both types help your duct last longer.

Safety is important, too. Fiberglass linings do not catch fire easily. They also keep out water and stop mold from growing. Many linings use special chemicals to fight germs. These products meet strict safety rules. They work even when air moves fast through the duct. Elastomeric foam linings stop water from building up inside the duct.

When you look at metal ducts with lining and other choices, you see some big differences:

Feature | Metal Ducts with Lining | Duct Liner | Duct Wrap |

|---|---|---|---|

Energy Efficiency | High | High | Medium |

Fire Resistance | Excellent | Good | Varies |

Moisture Protection | Strong | Good | Medium |

Noise Reduction | Good | Excellent | Low |

Installation Ease | Moderate | Easy | Easy |

Durability | High | Medium | Medium |

You might pick a duct liner if you want easy setup or less noise. Duct wrap is good for outside insulation but may not stop water or fire as well. Metal ducts with lining are strong and last a long time. They are best when you want safety and to save energy.

Sealing and insulation are important. Sealing metal ducts and using a good lining stops air leaks. This keeps warm or cool air inside the system. The U.S. Department of Energy says this lowers your bills and keeps your space comfy. It also keeps air pressure steady, so your HVAC system works safely.

Some linings, like elastomeric foam, have glue already on them. This makes putting them in faster and cleaner. Fiberglass linings are light and easy to hold inside the duct. Both types help you follow building rules for energy and safety.

Tip: Always make sure your duct liner or lining meets local rules and safety codes. This keeps your air clean and protects your money.

You can use metal ducts with lining in homes, offices, or big buildings. They work for new jobs or upgrades. If you want energy savings, safety, and something that lasts, this is a great choice.

You want your HVAC to use less energy and keep you comfy. Insulation helps a lot with this. Duct board insulation uses hard panels that slow down heat moving in or out. This keeps warm air inside in winter and cool air inside in summer. The r-value shows how good insulation is. Fiberglass duct insulation has an r-value of about 4.2 for each inch. Rigid foam insulation can have an r-value up to 8 for each inch. If the r-value is higher, your air stays the right temperature longer.

The table below compares duct board insulation and galvanized iron ducts:

Aspect | Pre-Insulated Duct Board | Galvanized Iron Ducts |

|---|---|---|

Thermal Insulation | Superior; reduces heat loss/gain, improves energy efficiency | Needs extra insulation for similar thermal performance |

Airflow Efficiency | Smooth surface lowers air friction, boosts efficiency | Standard metal may cause more air friction |

Moisture Resistance | Resists moisture, stops mold and corrosion | Can rust in damp places, needs more care |

Maintenance | Needs less upkeep, resists mold and corrosion | Needs more upkeep, can rust or need repairs |

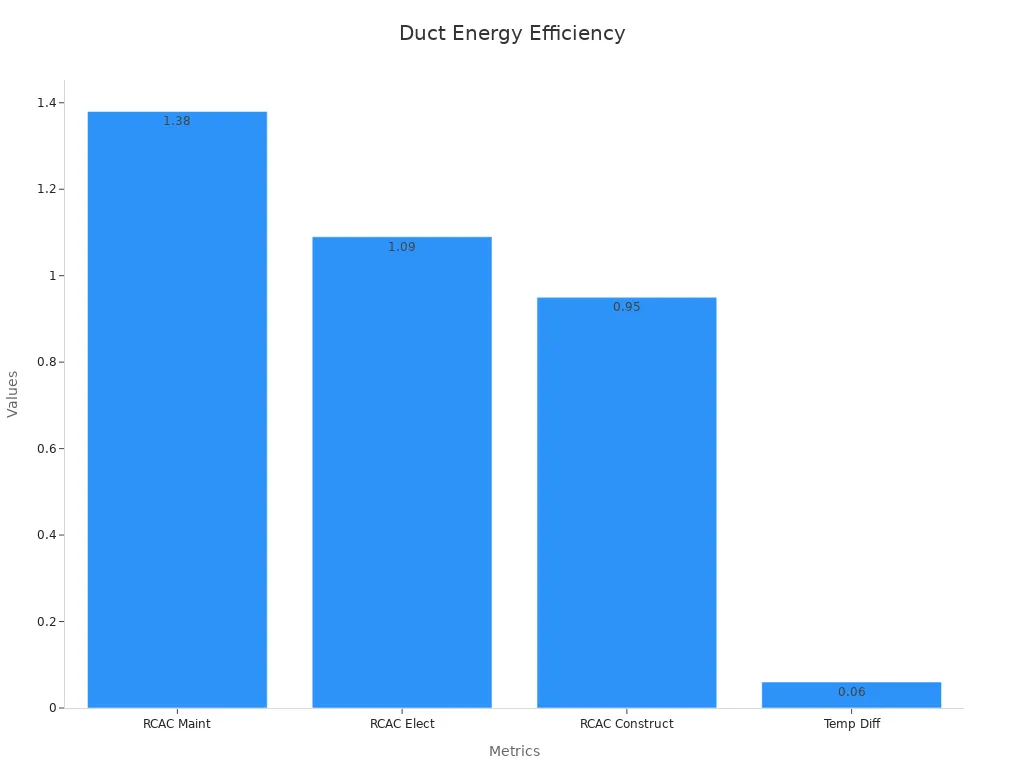

Duct board insulation gives better thermal performance and needs less care. The chart below shows pre-insulated ductwork is best for saving energy:

A higher r-value means better thermal performance. You save energy and money over time.

When you pick insulation, you want the best deal for your money. Duct board insulation costs more at first than fiberglass, but it saves you money later. You pay less for repairs and energy bills. Spray foam costs even more, but it seals every gap and saves the most energy. If you want to spend less, fiberglass is cheapest, but it may not last as long or save as much energy.

Here is a cost comparison for common duct insulation materials:

Material | Cost per sq ft | Typical R-Value | Notes |

|---|---|---|---|

Fiberglass | $1–$4 | 4–6 | Most affordable |

Reflective Coil | $4–$8 | 4–8 | Good for hot climates |

Spray Foam | $8–$13 | 6–8 | Best air seal, highest cost |

Foam/Duct Board | $6–$10 | 4–8 | Good balance of cost and value |

Think about where you live and your home's design. Higher r-value insulation costs more, but it saves more energy and money over time. Experts say you should talk to a pro to get the best mix of cost and energy savings.

Tip: Spending more on insulation now can mean lower bills and fewer repairs later.

You want insulation that fits your duct and is easy to put in. Duct board insulation comes in panels you can cut and fit fast. This makes it quicker to install than metal ducts, which need to be built on-site. Spray foam is flexible and fills every space, but you need special tools and training. Fiberglass and foam boards are easy for straight ducts but can be hard for tight bends.

Duct board panels: Easy to cut and fit, best for straight ducts.

Spray foam: Fills odd shapes, needs a pro to install.

Metal ducts: Customizable, but take longer to build and insulate.

If your ductwork has lots of curves, you may want spray foam or a flexible liner. For simple, straight ducts, duct board insulation is fast and keeps air the right temperature.

Note: Always check that your insulation fits well. Gaps or poor fits make your system work less well.

When you choose duct insulation, you want it to last. Duct board insulation gives good thermal performance, but it can get damaged more easily than some other options. If you bump or press on duct board, it may crack or break. Over time, moisture can get inside and cause mold. You need to check it often and fix any damage right away.

Sheet metal ducts stand out for durability. They use thick metal that resists dents and leaks. You can clean them more easily because the surface is smooth and non-porous. Mold does not grow as quickly on metal as it does on duct board. Flexible ducts can bend around corners, but they tear more easily and may not last as long.

Here is a quick comparison:

Insulation Type | Durability | Maintenance Needs |

|---|---|---|

Duct Board | Medium | Check for cracks, mold |

Sheet Metal | High | Easy to clean, rare repairs |

Flexible Duct | Low to Medium | Watch for tears, replace if damaged |

Tip: If you want less work over time, sheet metal ducts may be the best choice. Duct board works well, but you must keep an eye on it.

You should also think about cleaning. Duct board can trap dust and mold if it gets wet. You may need to clean it more often to keep your air safe. Metal ducts need less cleaning and last longer, which helps keep your HVAC system running well and keeps thermal performance steady.

Air quality matters for your health. Duct board insulation can sometimes release tiny fibers into the air, especially if it gets damaged. These fibers may bother people with allergies or asthma. If you keep the duct board in good shape, it usually does not cause problems.

Sheet metal ducts help keep air cleaner. The smooth surface does not trap dust or mold as easily. You can wipe or vacuum them without much trouble. Flexible ducts may collect dust and mold if they get wet or torn.

Some insulation types, like spray foam, can give off chemicals when new. You should always ask about VOCs (volatile organic compounds) before you pick an insulation. Low-VOC products help keep your indoor air safe.

Duct board: Watch for fiber release if damaged.

Sheet metal: Best for clean air, easy to clean.

Flexible duct: Can trap dust, needs careful cleaning.

Note: Always check your ducts for damage. Good maintenance keeps your air fresh and healthy.

Noise can travel through your ducts and bother you. Duct board insulation helps soak up sound. It makes your rooms quieter by blocking noise from your HVAC system. Flexible ducts also help reduce noise, but they may not last as long.

Sheet metal ducts do not block sound as well. You may hear more noise if you use only metal. You can add a liner or wrap to help with noise control. Spray foam also helps block sound and keeps thermal performance high.

Safety is important. Duct board insulation resists fire and meets safety codes. Sheet metal does not burn, so it is very safe in a fire. Flexible ducts may melt or burn faster, so you should check the safety rating before you use them.

Here is a summary table:

Insulation Type | Noise Reduction | Fire Safety |

|---|---|---|

Duct Board | Good | Good |

Sheet Metal | Low | Excellent |

Flexible Duct | Good | Fair to Good |

Spray Foam | Good | Good |

If you want quiet rooms and safe ducts, duct board and spray foam both work well. Sheet metal is safest for fire but may need extra help for noise.

You need to pick the best insulation for your job. Duct board insulation works well in places with straight ducts and open areas. You can cut panels to fit most shapes, but sharp corners or weird angles can be hard. If your building has lots of bends or tight spots, flexible duct liner or spray foam might be easier.

Duct board insulation is good for new homes, schools, or offices with simple layouts.

Flexible liners or spray foam work better for old buildings or places with many curves.

Metal ducts with lining are great for big commercial buildings.

Tip: Always check your local building rules before starting. Some places want certain insulation for fire safety or saving energy.

Taking care of your duct insulation helps your HVAC last longer. Duct board insulation needs to be checked often. Look for cracks, wet spots, or loose panels. If you find damage, fix it fast. This stops mold and keeps your air clean.

You can clean duct board insulation with a vacuum or soft brush. Do not use water, because it can soak in and cause mold. Metal ducts are easy to wipe, but still check for rust or loose lining. Flexible ducts can rip, so look at them often.

Here is a simple checklist for duct care:

Task | How Often | What to Look For |

|---|---|---|

Visual Inspection | Yearly | Cracks, mold, loose parts |

Cleaning | Yearly | Dust, debris |

Repair | As needed | Holes, water damage |

Note: Checking your ducts often keeps your air safe and your bills lower.

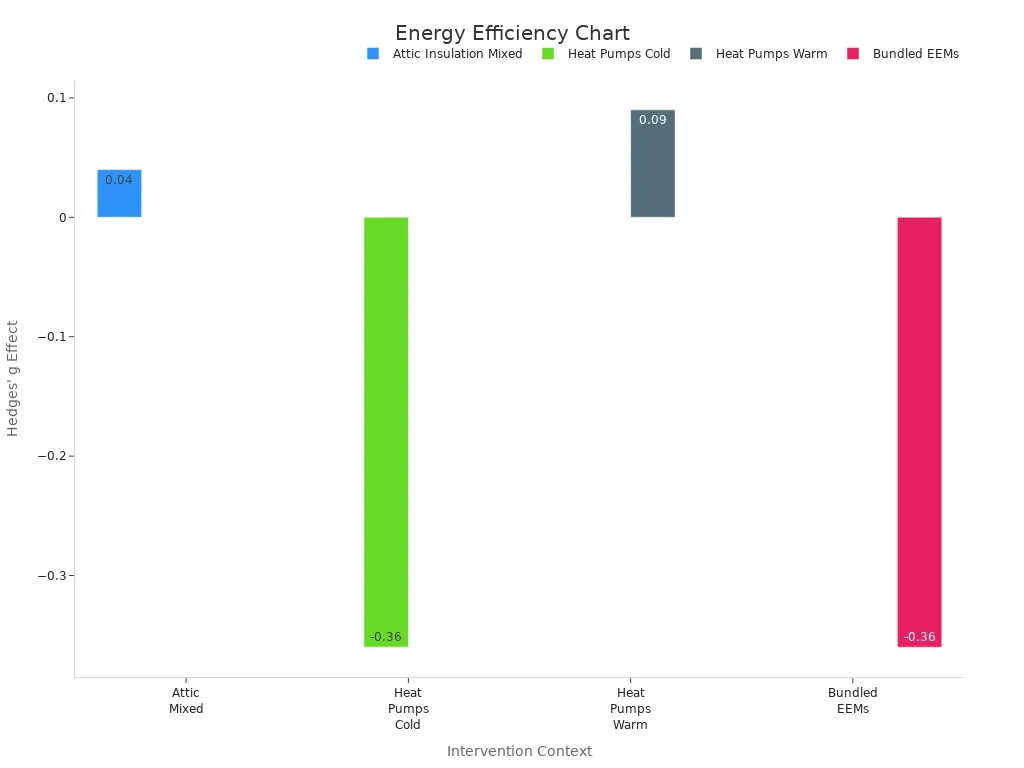

You want to know if duct board insulation saves money over time. Studies show insulation can cut energy use, but how much depends on your weather and how thick the insulation is. In cold places, thicker insulation saves more energy. In warmer places, the savings are smaller.

The table below shows how different insulation types change energy use:

Insulation Type | Climate | Energy Savings | Notes |

|---|---|---|---|

Attic/Loft Insulation | Cold | Small to large | Thick insulation works best |

Cavity Wall Insulation | Various | Moderate | Works in most homes |

Bundled Efficiency Measures | Various | High | Best results when combined |

You get the most from duct board insulation when you put it in the right spot and keep it in good shape. The money you spend at first comes back with lower bills and fewer repairs. If you live somewhere cold or use your HVAC a lot, you will save even more.

Remember: The best insulation depends on your building, your weather, and how you use your HVAC system.

Industry experts think duct board insulation is a good choice for many HVAC jobs. They say it helps buildings save energy and money. Experts use big studies to give advice. These studies get facts from companies, the government, and interviews. Experts check the facts to make sure they are right.

You can see how experts study duct board insulation in this table:

Evidence Aspect | Description |

|---|---|

Market Coverage | Reports talk about all insulation types for buildings and HVAC systems, including duct board. |

Quantitative Data | Studies show how much the market grows and how much people use duct board from 2018 to 2030. |

Expert Input | Experts and leaders answer questions and share their thoughts in interviews. |

Data Sources | Reports use facts from companies, government numbers, and other trusted sources. |

Validation Process | Groups of experts check the facts to make sure they are correct. |

Key Companies | Big brands like Saint-Gobain and Kingspan make a lot of duct board. |

Methodology | Researchers use different ways to collect and check facts, like forecasts and market sizing. |

Market Segmentation | Reports split the facts by product type, use, and region. |

Industry leaders say duct board insulation saves energy and meets safety rules. They say it works in many places, like homes and offices. Experts also say duct board insulation helps with noise and moisture. They suggest using it for straight ducts and when you want built-in insulation.

Many experts say duct board insulation gives good performance, safety, and value for most HVAC systems.

People who use duct board insulation talk about good and bad things. Many homeowners like that it is easy to put in. You can cut the panels to fit your ducts, which makes the job quick. Users say their homes are quieter after using duct board insulation. They also see lower energy bills.

Some people say duct board insulation keeps out water and stops mold. They feel safe because it does not burn easily and lasts a long time. People in cold or noisy places often pick duct board for these reasons.

There are some problems users talk about. Some say the panels can break if you are not careful. Others say duct board does not bend well around sharp corners. A few people worry about fibers in the air if the panels get damaged. Checking and cleaning your ducts often helps stop these problems.

Here are some things users say:

"I put in duct board myself. It was easy to cut and fit."

"My energy bills went down after I used duct board insulation."

"My house is much quieter now."

"I had to get a new panel after one broke during installation."

"I check my ducts every year to make sure the insulation is still good."

If you want to save money, feel comfortable, and stay safe, many people say duct board insulation is a smart pick. Just remember to check it often and fix any problems fast.

Based on the evidence, duct board insulation gives you strong energy savings, easy installation, and good noise control. It works best for straight ducts in homes and offices. You may want to choose it if you value cost and comfort.

Homeowners: Pick duct board for simple layouts and lower bills.

Facility managers: Use it for fast installs and code compliance.

HVAC pros: Recommend it for projects needing built-in insulation.

Always check your building's needs. Talk to an HVAC expert before you decide.

You find duct board insulation made from rigid fiberglass or mineral wool. It has a dense core that traps air. The outside layer often uses foil or mat to block moisture and add strength.

You can expect duct board insulation to last 20 to 30 years if you keep it dry and undamaged. Regular checks help you spot problems early. Good care extends its life.

Yes, you can install duct board insulation if you have basic tools and follow safety steps. Many people cut and fit panels at home. Wear gloves and a mask to protect yourself from fibers.

Duct board insulation can help keep air clean if you install and maintain it well. Damaged panels may release fibers. You should check your ducts often to keep air safe.

Spray foam seals every gap and gives a higher R-value per inch. Duct board costs less and installs faster. You pick spray foam for odd shapes. Duct board works best for straight runs.

Duct board insulation is safe if it stays sealed and undamaged. Loose fibers may bother sensitive people. You should inspect it yearly and fix any damage to protect your air.

You need to check for cracks, mold, or loose panels once a year. Clean dust with a vacuum or soft brush. Do not use water. Quick repairs keep your system working well.

You use duct board insulation in homes, schools, and offices. It fits best on straight ducts in open spaces. For tight bends or odd shapes, you may want flexible liner or spray foam.