Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

If you want the best cold room panels price, you should compare different suppliers and stay aware of market trends. Over the past five years, demand for cold room panels has surged because of better technology and a focus on energy efficiency. Today, industries like pharmaceuticals and organic food push this demand even higher. In 2023, the global market reached $3.2 billion, and experts project it will hit $5.7 billion by 2032 with a 6.5% annual growth rate. Knowing these trends helps you make smarter choices and secure better deals.

Compare different suppliers to find the best cold room panels price. This helps you secure better deals and understand market trends.

Invest in high-quality cold room panels for long-term savings. Better insulation reduces energy costs and maintenance expenses.

Consider the materials and thickness of panels. Thicker panels provide better insulation, which can save you money on energy bills.

Check for certifications when choosing panels. Certified products ensure safety and compliance with industry standards.

Request quotes from multiple suppliers. This allows you to compare prices, warranties, and support services effectively.

You use cold room panels to build spaces that keep products at specific temperatures. These panels form the walls, floors, and ceilings of temperature-controlled storage areas. You find them in places like food warehouses, walk-in refrigerators, and refrigerated trucks. Cold room panels help you maintain the right environment for sensitive goods.

Here is a table that shows the main functions and applications of cold room panels in commercial and industrial settings:

Function/Application | Description |

|---|---|

Temperature Control | Maintains specific temperature requirements for various food products to ensure quality and safety. |

Energy Efficiency | Reduces heat transfer, minimizing refrigeration load and leading to energy savings. |

Hygiene and Safety | Constructed from easy-to-clean materials that resist mold and bacteria, ensuring sanitary conditions. |

Versatile Applications | Used in cold storage warehouses, walk-in refrigerators, blast freezers, and refrigerated transport. |

Cold room panels differ from other insulation panels in several ways:

You get better hygiene and moisture control.

You install them faster, which saves time.

These panels last longer and are easier to repair.

Over time, you spend less money because they are more cost-effective.

Modern cold room panels outperform traditional insulation materials in many aspects.

You need to pay attention to the price of cold room panels because it affects your budget and long-term savings. Choosing the right panels for your temperature-controlled storage can help you save money in several ways. The table below highlights some potential cost savings:

Cost Saving Factor | Description |

|---|---|

Energy Efficiency | Superior insulation reduces energy needed to maintain low temperatures. |

Reduced Maintenance Costs | High-quality materials lead to fewer repairs and lower upkeep expenses. |

Improved Inventory Mgmt | Better temperature control helps in managing stock effectively, reducing waste. |

Tip: When you invest in high-quality cold room panels, you protect your products and lower your operating costs. You also make your temperature-controlled storage more reliable and efficient.

You should compare prices and features before you buy. This helps you find panels that fit your needs and budget. Cold room panels play a key role in keeping your products safe and fresh, so making a smart choice matters.

You will see strong growth in the cold room panels market as you move into 2025. The global market for cold room panels is projected to reach $11.5 billion by 2025, growing at a steady rate of 5.3% since 2020. This growth comes from several key trends:

The food processing and logistics industries continue to expand, driving up demand for cold room panels for sale.

More consumers want fresh and chilled foods, so you need better cold storage solutions.

E-commerce and online grocery shopping are increasing, which means you need efficient cold chain logistics.

New technologies, such as vacuum insulated panels (VIPs), help you save energy and improve cold room panels price value.

Environmental regulations push you to choose energy-efficient cold room panels.

Prefabricated cold rooms allow you to install storage faster and reduce labor costs.

Smart cold chain technologies give you real-time monitoring and better operational efficiency.

Sustainable practices, like using recycled materials, are becoming more important.

You will notice the fastest growth in the Asia-Pacific region. Urbanization and higher food distribution needs drive this trend. North America and Europe remain important markets, but their growth is slower. The Middle East, Africa, and South America also show potential, but at a more gradual pace.

Industries that drive demand for cold room panels include:

Food processing

Pharmaceuticals

Logistics

Food retail

Government regulations on food safety and the need for refrigerated storage solutions also increase demand.

When you look for cold room panel suppliers, you find a competitive landscape with several leading companies. Top cold room panel manufacturers offer advanced technology and strong customer support. Here is a table showing some of the top suppliers:

Manufacturer Name | Market Presence | Unique Selling Points |

|---|---|---|

Henan Tseason Panel Co., Ltd. | Strong global presence, 5 million sq. meters production capacity | Advanced technology, customer service excellence |

American Panel | Established leader in the market | High-performance panels, customization options |

Metl-Span | Strong global market presence | Superior thermal insulation, tailored solutions |

You can choose from a wide range of cold room panels for sale from these suppliers. Henan Tseason Panel Co., Ltd. offers polyurethane sandwich panels and prefabricated houses. American Panel provides customizable options with superior thermal insulation. Metl-Span delivers energy-efficient cold room panels for many applications.

Note: When you compare cold room panels price, always consider the reputation and unique features of each cold room panels manufacturer. This helps you find the best value for your investment.

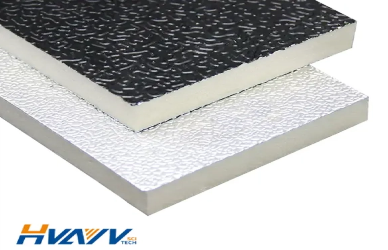

When you choose cold room panels, you first decide between insulated and non-insulated options. Insulated panels, often called structural insulated panels, have a core made from materials like expanded polystyrene or polyurethane. These panels provide strong insulation and structural support. Non-insulated panels lack this core and do not offer the same energy-saving benefits.

Here is a table to help you compare the pros and cons:

Advantages | Disadvantages |

|---|---|

Superior energy efficiency and insulation | Higher initial costs |

Quick and easy installation | Limited modification options after installation |

High structural strength and durability | Potential moisture issues if not properly sealed |

Improved indoor air quality | Requires specialized installation knowledge |

Versatile design options | Environmental impact of manufacturing |

You get better energy efficiency and lower operational costs with insulated cold room panels. Non-insulated panels may cost less at first, but you lose out on long-term savings and product protection.

The materials used in cold room panels play a big role in pricing. High-quality materials like polyurethane or insulated metal panels improve insulation and durability. These materials help you save energy and reduce maintenance over time. When you pick panels with better materials, you invest in long-term performance and lower energy bills. Cheaper materials may lower the upfront price, but you risk higher costs later due to poor insulation and frequent repairs.

Tip: Always check the core material and outer facings before you buy. Superior materials mean better insulation and longer-lasting cold room panels.

Performance features affect both the price and value of cold room panels. You should look for panels with strong thermal insulation, fire resistance, and hygiene properties. These features help you keep products safe and reduce energy use.

Key performance features include:

Thermal insulation for lower energy bills

Hygiene surfaces that resist bacteria and mold

Corrosion resistance for harsh environments

Easy installation and maintenance

Long-lasting durability

Panels with advanced features, such as PU insulated cores or antibacterial surfaces, may cost more. However, they give you better protection and lower costs over time.

When you want to secure the best cold room panels price, you need to understand the main factors that influence what you pay. Each element affects both the upfront cost and the long-term value of your temperature-controlled storage. Let’s break down the most important price factors so you can make an informed decision.

The materials used in cold room panels play a major role in determining price. You often see panels made from polyurethane, polystyrene, or insulated metal. High-quality materials improve durability and insulation, which helps you save money over time. Thicker panels provide better insulation, but they usually cost more upfront. Here’s how thickness impacts cold room panels price:

Thicker panels offer superior insulation, which can increase the initial cost but lower your energy bills in the long run.

For food processing and storage, you should choose panels with a thickness of 80 mm.

If you need to maintain temperatures below -10ºC to -20ºC, panels between 100 mm and 140 mm work best.

Ultra-freezing applications require panels with thickness ranging from 150 mm to 200 mm.

Tip: When you select the right thickness and material, you improve the efficiency of your temperature-controlled storage and reduce future expenses.

Insulation efficiency is a key factor in cold room panels price. Panels with better insulation help you maintain stable temperatures and lower your energy consumption. You may pay more for panels with advanced insulation, but you recover the higher cost through reduced utility bills. Efficient insulated panels keep your products safe and fresh, especially in food processing and storage environments. You also benefit from lower installation cost when you choose panels that fit your needs and space.

Certifications add value and impact cold room panels price. You should look for panels with recognized certifications, especially if you work in the food or pharmaceutical industries. These certifications guarantee safety, quality, and compliance with regulations.

ISO9001 and ISO4001 certifications show that panels meet international quality standards, which can raise the price.

CE certification ensures panels comply with environmental and safety standards, making them more marketable.

ISO 9001 confirms quality management systems.

HACCP verifies food safety protocols, which is crucial for food processing and storage.

CE marking indicates compliance with European safety standards.

UL listing allows access to North American markets.

Fireproof coatings are essential for freezer safety.

Testing standards include thermal performance, fire resistance, and structural load capacity.

In pharmaceutical storage, cold room panels must maintain temperatures between 2 to 8 degrees Celsius. Proper certifications ensure you meet strict safety and quality requirements.

Note: Certified panels may cost more, but they protect your products and help you comply with industry regulations.

Supplier reputation affects cold room panels price and the overall value you receive. You should evaluate suppliers based on quality, certifications, and fire resistance. Reliable cold room panel suppliers offer durable insulated panels and provide strong customer support. Here is a table to help you assess supplier reputation:

Criteria | Description |

|---|---|

Quality | Focus on durability and performance of insulated cold room panels. |

Certifications | Look for recognized certifications that ensure compliance with industry standards. |

Fire Resistance | Essential for insurance and safety in temperature-controlled storage installations. |

When you choose a reputable cold room panels manufacturer, you get panels that last longer and perform better. You also reduce the risk of costly repairs and downtime.

Tip: Always compare cold room panels price from multiple suppliers. Check their certifications and customer reviews before making a decision.

Other Key Factors to Consider:

Volume: Buying in bulk can lower the price per panel.

Customization: Special sizes or features may increase the cost.

Delivery: Shipping fees and lead times affect your total investment.

You should weigh all these factors when you compare cold room panels price. The right choice helps you maximize value and efficiency in your temperature-controlled storage.

You need to start with thorough research before you choose a supplier for cold room panels. Reliable suppliers help you get the best value and performance. Use these steps to guide your search:

Check insulation properties. Look for panels with high R-values to ensure strong insulation.

Evaluate panel material and thickness. Durable materials and the right thickness improve efficiency and lifespan.

Consider fire safety. Make sure panels are fire-rated and meet local regulations.

Examine the joining system. A good joining system keeps your cold room airtight and energy efficient.

Review supplier reputation and warranty. Read reviews, case studies, and warranty details to judge reliability.

Assess maintenance and longevity. Choose panels that are easy to maintain and last longer.

Balance your budget. Compare cost and quality for long-term savings.

You can use online reviews and industry certifications to help you select a trustworthy supplier. These reviews show how easy panels are to install, how well they maintain temperature, and how responsive customer service is. Certifications prove that the supplier meets strict standards for energy efficiency and durability. This gives you peace of mind when you make your decision.

Tip: Always compare different suppliers using an insulated panel comparison. This helps you see which panels offer the best insulation, safety, and value.

Requesting quotes is a key step in finding the right cold room panels. You need clear and detailed information to compare prices accurately. Follow these steps to get the best results:

Compile a list of reputable suppliers. Use online research, referrals, and reviews.

Check their credibility. Look at certifications, warranties, and customer feedback.

Analyze their product range. Make sure the panels fit your size, temperature, and energy needs.

Request detailed quotations. Ask for installation and maintenance costs, and check for hidden fees.

Compare quotes. Look at delivery timelines and after-sales support.

Visit client references or inspect existing installations. Confirm the quality and reliability of the panels.

When you request quotes, include all your requirements. This ensures you get accurate pricing and avoid surprises later. Comparing quotes from several suppliers helps you find the best deal for your cold room panels.

Quote Checklist | Why It Matters |

|---|---|

Product Specifications | Ensures compatibility with your storage needs |

Installation Costs | Reveals total investment, not just panel price |

Maintenance Fees | Shows long-term expenses |

Delivery Timeline | Helps you plan your project schedule |

After-Sales Support | Guarantees help if issues arise |

Supplier support services add value to your investment in cold room panels. You should look for suppliers who offer professional installation, staff training, and maintenance contracts. These services help you keep your cold room running smoothly.

Professional installation ensures skilled technicians set up your panels correctly.

Training helps your staff operate and maintain doors and panels safely.

Maintenance contracts provide regular check-ups to keep panels in top condition.

Spare parts availability means you get quick replacements when needed.

Good support services reduce downtime and protect your products. When you choose a supplier with strong support, you get more value from your cold room panels over time.

Note: Reliable support and service make a big difference in the long-term performance of your cold room panels. Always ask about these services before you buy.

You can often secure a better cold room panels price by preparing before you talk to cold room panel suppliers. Start by researching the average cold room panels price in your region. Gather quotes from several cold room panel manufacturers. This gives you a strong position when you negotiate. Always ask suppliers about discounts, especially if you see cold room panels for sale. You should also check if the cold room panels manufacturer offers seasonal promotions or special deals.

Tip: Bring up competitor pricing during your discussion. Suppliers may match or beat a competitor’s cold room panels price to win your business.

Use a checklist when you negotiate:

Confirm the cold room panels price includes delivery and installation.

Ask about warranty and after-sales support.

Request a breakdown of costs for materials, labor, and any extras.

Bulk buying can help you lower your cold room panels price. When you order a large quantity from cold room panel suppliers, you often get a better rate per panel. Many cold room panel manufacturers offer volume discounts for big projects. You should ask suppliers to provide a price list for different order sizes. This helps you see how much you save as your order grows.

Order Quantity | Price per Panel | Savings (%) |

|---|---|---|

10-50 panels | $X | 0% |

51-100 panels | $X-5% | 5% |

101+ panels | $X-10% | 10% |

Note: Always confirm that the cold room panels for sale meet your quality standards, even when you buy in bulk.

Plan for future expansion when you negotiate your cold room panels price. If you expect your storage needs to grow, discuss flexible options with your cold room panels manufacturer. Some cold room panel suppliers offer modular systems or price locks for future orders. You can also ask about trade-in programs or upgrade discounts.

You should keep a record of your agreement with the cold room panel suppliers. This makes it easier to add more panels later without renegotiating the entire contract. Planning ahead helps you save money and ensures your cold room panels price stays competitive as your business grows.

You should always check the warranty when you compare cold room panels price. A strong warranty protects your investment and shows that cold room panel manufacturers trust their products. Most reputable cold room panel suppliers offer warranties that cover defects in materials and workmanship. You need to ask each cold room panels manufacturer about the length and coverage of their warranty. Some cold room panels for sale come with extended warranties, which can save you money if problems arise.

Tip: Always read the warranty terms before you buy. Look for coverage on insulation performance, panel joints, and surface coatings. If a cold room panels manufacturer offers a longer warranty, you often get better value for your cold room panels price.

Here is a quick checklist for evaluating warranties:

Length of warranty period

Coverage for insulation and structure

Support for repairs or replacements

Exclusions and limitations

A good warranty helps you avoid unexpected costs and keeps your cold room panels price predictable.

You want your cold room panels price to deliver value over many years. Long-term performance depends on the quality of materials, insulation, and installation. Leading cold room panel manufacturers design panels to resist moisture, mold, and corrosion. This means you spend less on repairs and replacements. Cold room panel suppliers who use advanced technology often provide panels that keep energy costs low.

You should also consider how easy it is to clean and maintain your panels. Panels with smooth, hygienic surfaces help you meet food safety standards. When you choose cold room panels for sale with proven durability, you protect your products and lower your total cost of ownership.

Remember: The best cold room panels price is not always the lowest upfront cost. Focus on long-term savings, energy efficiency, and reliable support from your cold room panels manufacturer.

You can secure the best cold room panels price by following a clear plan. Start by listing your storage needs. Write down the size, temperature range, and any special features you want. Next, research cold room panel suppliers and cold room panel manufacturers. Look for reviews and check if they offer cold room panels for sale that match your requirements.

Request quotes from at least three cold room panel suppliers. Compare the cold room panels price, but also look at warranty, support, and delivery times. Use a table to organize your findings:

Supplier Name | Cold Room Panels Price | Warranty | Delivery Time | Support Services |

|---|---|---|---|---|

Supplier A | $X | 5 years | 2 weeks | Yes |

Supplier B | $Y | 3 years | 1 week | No |

Supplier C | $Z | 10 years | 3 weeks | Yes |

Ask each cold room panels manufacturer about bulk discounts and future expansion options. Always read the warranty details before you buy. Choose cold room panels for sale that offer the best value, not just the lowest cold room panels price.

Tip: Keep all your quotes and notes in one place. This helps you make a smart decision and track your cold room panels price over time.

You should avoid common mistakes when searching for the best cold room panels price. Do not focus only on the lowest price. Cheap panels may cost more in repairs and energy bills. Always check if the cold room panel manufacturers have proper certifications. Uncertified panels can lead to safety issues and lost products.

Do not skip reading the warranty. Some cold room panel suppliers offer short warranties or limited coverage. This can leave you with extra costs. Never ignore after-sales support. Good cold room panels manufacturer support helps you solve problems fast.

Alert: If a cold room panels price seems too low, ask why. Sometimes, low prices mean poor quality or hidden fees.

You should also avoid rushing your decision. Take time to compare cold room panels for sale, check supplier reputation, and review all terms. This careful approach helps you get the best cold room panels price and long-term value.

You can secure the best cold room panels price by staying aware of market trends, comparing cold room panel suppliers, and negotiating with cold room panel manufacturers. Use these steps:

Research cold room panels for sale and compare features.

Request quotes from several cold room panels manufacturer options.

Check warranties and support services.

Stay updated on industry changes to maximize value. Start comparing cold room panels price and suppliers today to protect your investment and improve your cold storage efficiency.

You use cold room panels in cold storage warehouses, walk-in coolers and freezers, and pharmaceutical cold chain storage. These panels help you keep products at safe temperatures and improve energy efficiency in many industries.

You should select panel thickness based on your temperature needs. Thicker panels provide better insulation for colder environments. Ask your supplier for recommendations that match your specific storage requirements.

You can install some panels if you have experience with construction. For best results, hire professionals. Proper installation ensures your panels perform well and last longer.

You should clean panels regularly with mild detergent and inspect for damage. Check seals and joints to prevent air leaks. Routine maintenance helps your panels last longer and keeps your storage safe.

Yes, you can use cold room panels for food and medicine. They meet strict hygiene standards and help you maintain the right temperature in walk-in coolers and freezers, as well as pharmaceutical cold chain storage.