Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

You see cold room panels prices change based on quality. When you choose panels, you need to look at the materials, thickness, and insulation. The market keeps growing fast.

The Cold Room Panels Market is projected to reach 2,500 USD Million in 2025.

By 2035, it is expected to grow to 4,500 USD Million.

If you select advanced insulation or custom-built panels, you pay more. Finding the right balance helps you save money and get better performance.

Cold room panel prices increase with quality. Investing in high-quality panels leads to better insulation and lower energy costs over time.

Key factors like insulation material, thickness, and joint systems affect both performance and price. Choose wisely to balance upfront costs with long-term savings.

Certified panels ensure safety and compliance with industry standards. While they may cost more initially, they provide peace of mind and often reduce operational expenses.

Consider your specific storage needs when selecting panels. Different industries have unique requirements that influence the type of panels you should choose.

Always compare features and after-sales support from suppliers. This helps you find the best value and ensures reliable performance for your cold storage needs.

You see a direct link between cold room panels prices and the quality of the panels you choose. As the market grows, especially in 2025, more industries need reliable cold storage. This demand pushes both quality and prices higher. Food, beverage, and pharmaceutical companies want strict temperature control, so they often invest in higher quality panels. When you look at cold room panels prices, you notice that better insulation and advanced features usually mean a higher price tag. However, these features also bring better performance and energy savings.

Several key factors shape the quality of cold room panels and influence their prices. You should pay attention to these when comparing options:

Quality Factor | Description | Impact on Price |

|---|---|---|

Size and Capacity | Larger cold rooms need more materials and complex installation. | Higher costs due to increased material usage. |

Insulation and Materials | High-quality insulation improves thermal performance and energy efficiency. | Premium materials raise initial costs but lower operational costs. |

Temperature Range | Cold rooms for extreme temperatures need specialized components. | Higher upfront costs due to advanced systems. |

Customization | Tailored cold rooms can add significant costs based on features. | Customization can increase costs by 15%-30%. |

Refrigeration System | The type and efficiency of the refrigeration system affect overall costs. | Advanced systems may have higher initial costs but save energy. |

Poor insulation lets heat in and cold air escape, which hurts efficiency.

Airtight panels help you keep stable temperatures and reduce energy loss.

Well-designed joints stop warm air leaks, lowering the load on your refrigeration system.

High-quality panels cut energy use by blocking heat transfer.

Good panels also keep out moisture, so your cold room stays at the right temperature.

You notice that cold room panels prices rise as you move toward higher quality. The market for cold room panels keeps growing, with values expected to reach $2.5 billion in 2025. This growth comes from the need for better cold storage solutions. When you choose panels with advanced insulation or custom features, you pay more upfront. However, these panels often save you money over time by lowering your energy bills.

Higher quality panels cost more because they use better materials and technology.

Panels built for extreme temperatures or special uses need extra features, which increase prices.

Custom designs and larger sizes also add to the cost.

Investing in high-quality cold room panels can help you avoid problems like temperature swings or high energy use.

Tip: When you compare cold room panels prices, always check the quality factors. A higher price often means better performance and lower long-term costs.

When you choose cold room panels, you need to understand what makes them high quality. Each factor plays a role in temperature control, durability, and long-term performance. Let’s break down the main features that affect how cold room panels work in your facility.

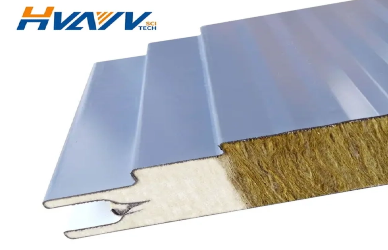

Insulation materials determine how well cold room panels keep temperatures stable. You want panels that offer high insulation efficiency and precise temperature control. Here are the most common options:

Polyurethane (PU) panels give you exceptional thermal insulation. They have low thermal conductivity, which helps you achieve high insulation efficiency and save energy.

Polyisocyanurate (PIR) panels provide even lower thermal conductivity than PU. These panels work best when you need precise temperature control in demanding environments.

Expanded Polystyrene (EPS) is also used in cold room panels. EPS does not match the insulation performance of PU or PIR, but it can be a cost-effective choice for less strict temperature control needs.

PU insulation stands out for its mechanical strength and moisture resistance. PIR panels excel in environments where you need strict and precise temperature control.

Panel thickness affects both insulation and durability. You see the ideal thickness for cold room panels ranges from 80mm to 200mm. Most facilities prefer panels between 80mm and 150mm. This range gives you high insulation efficiency, quick assembly, and easy maintenance. Thicker panels help you maintain precise temperature control, especially in cold rooms that store sensitive products.

Panels in the 80mm-150mm range dominate the market.

This thickness supports high insulation efficiency and lowers installation costs.

Thicker panels provide better temperature control for cold storage.

Joint systems connect cold room panels and prevent air leaks. You want a system that keeps your cold room airtight and supports precise temperature control. Here’s a comparison:

Joint System | Description | Impact on Durability and Temperature Control |

|---|---|---|

Tongue-and-Groove | Panels fit together with male and female grooves, sealed with sealant. | Prevents cold bridge effect; maintains temperature fluctuation within 0.5℃. |

Cam-Lock Mechanism | Uses integrated metal cams for uniform compression and airtight seal. | Critical for preventing thermal bridging and air/moisture infiltration. |

Airtight joints help you avoid temperature swings and keep your cold room panels working efficiently.

Certifications show that cold room panels meet safety and performance standards. You should look for panels with the right certifications to ensure quality and compliance.

Certification Type | Importance |

|---|---|

Fire Certifications | Essential for ensuring materials retard fire propagation and meet stringent building code requirements. |

Energy Certifications | Ensures compliance with energy efficiency codes and R-value requirements for cooler and freezer panels. |

Electrical Safety Certifications | Guarantees safety of electrical components to prevent hazards like fires and shocks. |

Certified cold room panels give you peace of mind and help you meet industry regulations. You get better durability and reliable temperature control.

When you compare cold room panels prices, you need to look at several quality factors. Each factor—material, thickness, joint system, and certification—affects the price you pay and the performance you get. Understanding these differences helps you make the best choice for your storage needs, especially if you work with food or pharmaceuticals.

The insulation material inside cold room panels plays a big role in both performance and price. You find that panels made with Polyurethane (PU) or Polyisocyanurate (PIR) offer better thermal insulation than those made with Expanded Polystyrene (EPS). PU and PIR have lower thermal conductivity, which means they keep temperatures stable and save energy. However, these materials cost more than EPS. If you choose EPS, you pay less upfront, but you may spend more on energy over time.

Quality Level | Insulation Type | Thermal Conductivity (W * K / m) | Cost Implication |

|---|---|---|---|

Low | Expanded Polystyrene (EPS) | 0.038 | Lower cost due to cheaper material |

Medium | Polyurethane (PU) | 0.019-0.025 | Moderate cost with decent insulation |

High | Polyisocyanurate (PIR) | 0.019-0.025 | Higher cost for superior insulation |

Low-quality panels use EPS, which costs less but does not insulate as well.

Medium-quality panels use PU, which balances cost and performance.

High-quality panels use PIR, which gives you the best insulation but at a higher price.

If you store food that needs strict temperature control, you benefit from investing in higher quality materials.

Panel thickness affects both the R-value (a measure of insulation) and the price. Thicker cold room panels provide better insulation, which helps you keep food at safe temperatures and reduces energy use. However, thicker panels cost more. For example, a 100mm thick PIR panel can cost 50% to 100% more than a 50mm panel of the same type and size. You need to choose the right thickness based on your storage needs and budget.

Thicker panels mean higher prices but better energy savings.

Most cold room panels for food storage use thicknesses between 80mm and 150mm.

If you need to store sensitive products, thicker panels are worth the investment.

The way cold room panels connect also affects the price. Joint systems keep your cold room airtight and prevent leaks. You can choose from single, double, or triple joint systems. Each type offers different levels of protection and cost.

Joint Type | Description | Cost Implication |

|---|---|---|

Single Joint | Improved standard joint for better airtightness | Reduces leaks, lowers maintenance costs |

Double Joint | Hermetic sealing, prevents air leaks during temp changes | Essential for high-value storage, higher upfront cost |

Triple Joint | Continuous wall, few interruption points | Best insulation, reduces long-term operational costs |

Single joints cost less but may not be enough for strict food storage.

Double and triple joints cost more but give you better protection and lower maintenance over time.

Certifications add to the price of cold room panels, but they also guarantee safety and performance. Panels with fire, energy, or electrical safety certifications meet strict industry standards. You pay a premium for these certifications, but you get peace of mind and often lower insurance costs.

Certified panels cost more upfront.

You meet food safety and building code requirements.

Certified panels often last longer and perform better.

You can see how these factors affect cold room panels prices by looking at a sample price table. Prices vary by supplier, material, and thickness.

Quality Level | Insulation Type | Thickness (mm) | Joint System | Certification | Price Range (USD) |

|---|---|---|---|---|---|

Low | EPS | 50-80 | Single | Basic | $12 - $20 |

Medium | PU | 80-120 | Double | Standard | $16 - $30 |

High | PIR | 100-150 | Triple | Premium | $560 - $11,627 |

Note: Prices from top suppliers like Kingspan, Accio, and Henan Tseason show a wide range. For example, Kingspan offers insulated panels from $13.08 to over $11,000, depending on size and features.

When you shop for cold room panels, you should compare not just prices but also features and benefits. Leading suppliers like Henan Tseason, American Panel, and Kingspan offer panels with high insulation, reliable temperature control, and easy installation. These features help you save on energy and maintenance, especially if you store food or sensitive products.

Feature/Benefit | Cold Room Panels | Traditional Refrigeration Systems |

|---|---|---|

Energy Efficiency | High insulation reduces energy use | Higher energy use |

Temperature Control | Reliable for precise control | Accurate settings, but less efficient |

Installation and Maintenance | Quick install, minimal maintenance | Regular maintenance needed |

Cost Considerations | Higher initial cost, long-term savings | Lower upfront cost, higher ongoing costs |

Tip: Always compare the features, certifications, and after-sales support from different cold room panel suppliers. This helps you find the best value for your investment.

You can see that cold room panels prices depend on many factors. By understanding these differences, you make smarter choices for your food storage or other cold storage needs.

When you evaluate cold room panels, you need to balance the initial cost with long-term performance. Many buyers focus on the price tag, but you should look deeper. Consider these steps:

Compare initial cost with expected savings over time.

Check the R-value and thermal resistance for better temperature control.

Estimate energy consumption and future operating costs.

Think about how panels can help reduce your carbon footprint.

Calculate the return on investment based on energy savings.

Panels with higher insulation, such as polyurethane foam, can save you up to 40% in energy costs compared to older materials. Advanced insulation may cost more upfront, but you benefit from reduced operating costs and better temperature control year after year.

Durability and maintenance play a big role in cost considerations. Cold room panels must keep temperatures stable and prevent warm air from entering. If insulation breaks down, you risk hot spots and temperature swings. Moisture infiltration can damage panels and lead to biological growth or ice buildup. Poor installation and maintenance can cause immediate failure or higher energy bills.

Panels with strong insulation resist moisture and last longer.

Regular installation and maintenance checks help you avoid costly repairs.

Durable panels support consistent temperature control and protect your products.

You should always ask about installation and maintenance requirements before buying. Reliable panels mean fewer problems and lower costs over time.

Total cost of ownership includes more than just the purchase price. You need to think about energy efficiency, maintenance, and long-term savings. The table below shows how different features impact energy use:

Feature | Impact on Energy Efficiency |

|---|---|

High-efficiency compressors | Reduces energy consumption |

Variable speed fans | Adjusts airflow based on demand |

Smart controllers with sensors | Optimizes temperature management |

Energy-saving defrost systems | Minimizes energy waste during defrost |

Superior insulation and modern systems lower utility bills and help you achieve better temperature control. Low-maintenance designs reduce downtime and keep your cold room panels working efficiently. When you choose high-quality panels, you invest in long-term value and reliable performance.

Tip: Always include cost considerations for installation and maintenance when planning your budget. This helps you avoid surprises and ensures your cold room panels deliver the best value.

You need to match cold room panels to your specific temperature control requirements and storage applications. Each facility has unique needs for temperature-controlled storage. Consider these factors when selecting insulated panels:

Insulation quality affects how well you maintain temperature control. Material type, thickness, and installation quality matter.

Door usage and sealing play a role. Frequent opening or poor seals can cause temperature fluctuations in controlled environments.

Refrigeration system performance impacts temperature-controlled storage. Efficient compressors and clean evaporators help keep stable temperatures.

Ambient temperature outside the cold room influences internal temperature control.

Product load and arrangement affect airflow and temperature distribution in temperature-sensitive storage.

Cold room size and design determine how well you manage controlled environments.

Monitoring and control systems help you maintain consistent temperature control.

Power supply stability ensures reliable temperature-controlled storage.

Maintenance practices, such as regular inspections and cleaning, support optimal performance.

You should assess these factors before choosing insulated metal panels for walk-in coolers and freezers or other temperature-controlled storage solutions.

You want to plan your budget carefully when investing in cold room panels. Different industries require different panel qualities for controlled environments. The table below shows how storage applications influence your choice:

Industry | Key Requirements |

|---|---|

Food Industry | Hygiene requirements, temperature fluctuation tolerance, chemical resistance |

Pharmaceutical Industry | Temperature control accuracy, clean room standards, validation requirements |

Logistics and Distribution | Impact resistance, quick installation, modularity flexibility |

You should estimate operational costs, including energy use and maintenance, when planning for insulated panels. Higher quality panels may cost more upfront, but they often reduce operational costs over time. Quick installation can also lower labor expenses and minimize downtime in controlled environments.

When you evaluate cold room panel suppliers, you need to ask the right questions to ensure quality and value:

What insulation materials and thickness do you offer for temperature-controlled storage?

How do your panels rate for energy efficiency in controlled environments?

What warranty terms cover long-term performance?

Can you provide detailed quotations, including installation and maintenance costs?

Are there any hidden fees in your quotes?

What certifications and customer feedback support your credibility as cold room panel manufacturers?

Do you offer refurbished insulated panels that have been professionally inspected?

You should compare cold room panels prices, features, and after-sales support from different cold room panel suppliers. This approach helps you find the best solution for your temperature-controlled storage needs and ensures reliable performance in controlled environments.

You see that panel quality directly impacts cold room panels prices and long-term value. High-quality panels improve insulation and reduce energy costs. Inferior materials can increase operational expenses. When you compare cold room panel suppliers, follow these steps:

Check insulation properties and panel thickness.

Review supplier reputation and customer feedback.

Consult experts for installation and layout planning.

Properly sealed joints prevent air leaks and help maintain temperature control. Choose cold room panels for sale from trusted cold room panel manufacturers to ensure reliable performance.

You see insulation material, panel thickness, and joint system design impact cold room panels prices. Certified panels from trusted cold room panel manufacturers also cost more. You should compare features from top cold room panel suppliers before buying.

Tip: Always check if cold room panels for sale meet your temperature control needs.

You should review cold room panel suppliers for product quality, certifications, and after-sales support. Ask about insulation types, thickness options, and warranty terms. Reliable cold room panels manufacturer brands offer better value and long-term performance.

Certified cold room panels prices are higher, but you get better safety and energy efficiency. You meet industry standards and reduce risks. Cold room panel manufacturers with certifications help you avoid costly problems.

You can search online for cold room panels for sale from leading cold room panel suppliers. Many cold room panels manufacturer companies offer quick shipping and installation. Compare delivery times and customer reviews before you order.

Thicker panels usually cost more, but you save on energy bills. Cold room panels prices depend on insulation type and joint system. You should balance upfront cost with long-term savings when choosing from cold room panel manufacturers.